Already covering over 70,000 of its excavators, wheel loaders and ADTs worldwide, DoosanCONNECT is set to reach even further

Whatever the size of project, in order to maximise operating efficiency, fleet managers are increasingly looking to implement smart solutions, and telematics is very much part of the package. Data is now the world’s most valuable currency, and collecting and analysing it the key to success.

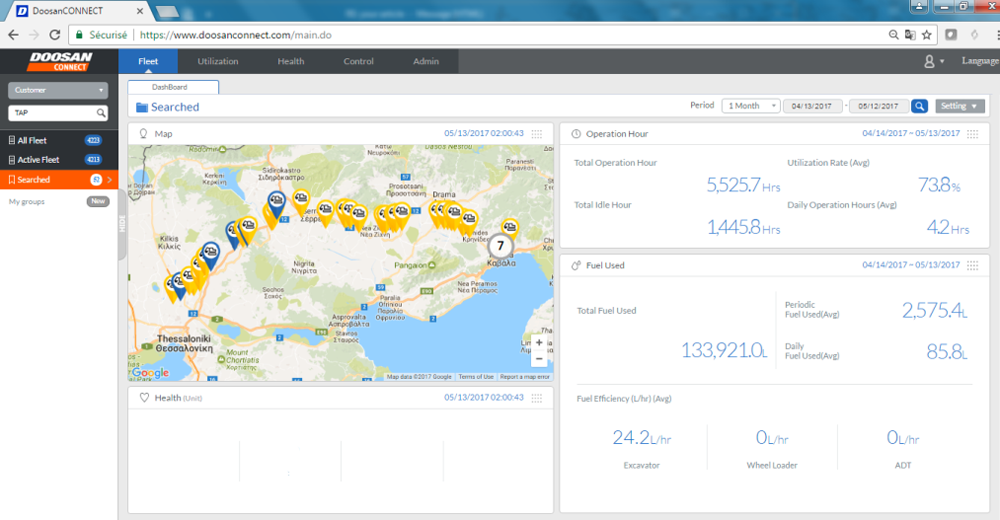

That’s why the real-time monitoring that DoosanCONNECT provides is an invaluable weapon in the fight to increase efficiencies in site management and equipment operation. It can check engine and hydraulic systems, and provide information, mapping and visuals on their location and availability. Efficient equipment deployment can be implemented via a monthly report on operations, with detailed information on service hours and fuel consumption, as well as timely responses to filter and oil replacement.

With the launch of a mobile app for Apple and Android devices new functions will now include directions to machines; call service – whereby the app connects the customer directly with the Doosan dealer’s service operation – and a Chat option to send messages to the service provider.

Expanded Scope

The Korean manufacturer plans to further expand the types of equipment covered, and develop various services based on the telematics system to manage consumables and provide enhanced maintenance packages. The system provides comprehensive information about machine performance in a dual mode (satellite, mobile network). As such, it is the only tool of its type capable of providing this level of information, delivering insightful and cost-saving data about equipment to help customers work more effectively.

This telematics technology allows fleet managers to compile a number of reports, including fleet status; machine details; machine location; operating hours; fuel usage; engine idle time vs work time; machine error codes; engine warning system; maintenance history and utilisation reports.

According to Doosan, the DoosanCONNECT telematics system provides significant benefits for customers through the use of operational data that help improve efficiency, such as altering machine idle times based on fuel usage, machine security and safety.

The system can support multiple Doosan machines in different locations, helping customers to monitor machine utilisation rates to assess that the right mix of machines is being used; it can also guide drivers to help them to operate equipment with higher efficiency and to locate replacement machines in the event of maintenance work or breakdowns, all under the umbrella of vigorous anti-theft and theft recovery protection systems. Customers can monitor the physical location of their Doosan machines, ensuring they are where they are supposed to be, which helps prevent equipment theft.

The system can support multiple Doosan machines in different locations, helping customers to monitor machine utilisation rates to assess that the right mix of machines is being used; it can also guide drivers to help them to operate equipment with higher efficiency and to locate replacement machines in the event of maintenance work or breakdowns, all under the umbrella of vigorous anti-theft and theft recovery protection systems. Customers can monitor the physical location of their Doosan machines, ensuring they are where they are supposed to be, which helps prevent equipment theft.

Operational data also gives owners insight into monitoring the machine’s fuel efficiency and the selected power mode in different applications. This is helpful to determine if an operator can make adjustments in order to do the same work with less diesel fuel. Doosan machines provide operators with various power modes to help them best match the power needed for specific applications.

If a problem does arise, the system alerts owners, helping reduce machine downtime. The website reports fault and warning codes, and, because they will have more data about what is wrong with the machine, owners – or their dealers – are better prepared to fix the problem when they respond. Doosan dealers can view the problem on the DoosanCONNECT™ website to help diagnose an issue, without physically being in the same location as the machine.

With all of the information available, business owners can make better estimates when completing job bids and planning for jobs. Accurate machine usage reports, such as the number of hours a machine was used for a particular job, help owners respond to new business opportunities.

Trans Adriatic Pipeline (TAP) Project

Nearly 90 per cent completed by the end of September 2019, the Trans Adriatic Pipeline (TAP) Project provides a good illustration of how DoosanCONNECT can be used on construction contracts around the world. Since work began in 2016, the TAP Project has utilised well over 50 new Doosan excavators in the construction phase. Every day hundreds of metres of TAP’s Right of Way (ROW) are cleared, strung, welded, lowered into the trenches and backfilled, in line with the project construction steps and schedule.

For the construction of about 360 km of the pipeline in Greece, 52 new Doosan excavators alone were used on this section of the works. The Doosan excavators were chosen following a competitive analysis of eight leading excavator manufacturers carried out by the Bonatti-J&P Avax s.r.l. joint venture, which was awarded the EPC (Engineering, Procurement, Construction) contract for this section of the TAP Project.

The Bonatti-J&P Avax s.r.l. joint venture chose the Doosan brand to provide the power and reliability required for the contract, purchasing the 52 new Doosan crawler excavators for the excavation work and for the laying of the 1.2 m (48 in.) diameter pipes in the project. The Doosan excavator fleet comprised models from 30 to 55 tonne and included 10 DX300LC-5, 20 DX340LC-5, 10 DX380LC-5 and 12 DX530LC-5 crawler excavators.

Doosan excavators have been working hard in a range of different applications from preparatory work, including grading, removing trees and site clearance, lifting gas pipes to lay them out or ‘string’ them, digging trenches using hydraulic breakers or buckets, to loading crushing and screening equipment to create backfill for the trenches that does not damage the pipes.

DoosanCONNECT and Service Packages

The contract for the 52 Doosan excavators included a full service package with a dedicated service team available around the clock. Service has been handled directly by Ergon Tzanidakis, the Doosan dealer in Greece.

As a web-based fleet management system that has successfully monitored the performance and security of the machines, as well as promoting preventative maintenance, the support it has afforded has been greatly appreciated by Bonatti-J&P Avax s.r.l.,.