A top performer in tough conditions – that’s how New Holland is describing its wheel loaders. Construction Plant News puts the questions to the manufacturer.

What does New Holland have in the range and what sectors is the company targeting?

New Holland W110 D, W130 D, W170 D and the new W190 D wheel loaders are designed to meet the needs of both large and small-scale construction companies, where loading performance is critical. These machines deliver tough, versatile and reliable performance in the toughest quarries, 24-hour recycling plants and countless intensive industrial applications.

Tell us about some of the new developments in the operator’s workstation?

The fully ROPS and FOPS certified cab does, indeed, feature a number of improvements, not least all-round visibility. A seat mounted joystick control features a fully adjustable armrest ensuring that all the key functions are at your fingertips allowing you to tailor your controls through the new 8in. touchscreen dashboard display. Now you can set a variety of parameters, such as engine modes, starting gear and flow rates as well as allowing you access to several menus, which include service settings, machine information and even the operator’s manual. The cab is mounted on viscous oil suspension blocks which reduce vibration whilst noise levels are as low as 68dB(A).

What has been done to achieve Stage V?

New Holland Wheel loaders are fully compliant with Stage V emissions regulations, allowing you to achieve more than 95 per cent NOx conversion with reduced ADBlue usage. The machines are powered by 4.5litre and 6.7litre NEF High Efficiency Selective Catalytic Reduction HI-eSCR engines which are fitted with the latest ECOBlue and HI-eSCR 2 technology. This is achieved through an electronic control unit that manages the engine and exhaust, precisely matching engine load emissions and after treatments using a dedicated closed loop system which continuously monitors NOx levels in the exhaust.

We understand that a key design feature of the D series loaders is the positioning of the engine behind the rear axle. What does that achieve for the end user?

The design allows not only unhindered access to engine service points but also a cooling cube between the engine and transmission. This reduces power consumption through a reversible fan option that forces air through each of the five radiators, ensuring that each one benefits from a direct flow of cool air thus reducing the load on the cooling fan.

What boom options and features have been made available?

A mighty Z-bar linkage boom constructed from 45mm thick steel is fitted as standard to all New Holland Wheel Loader models. A choice of two booms allows you to enable the machine to be specified to meet different handling priorities.

- Standard Boom – perfect for demanding construction settings where heavy duty shifting of gravel or earth is required.

- Long Reach Boom – increases dump heights by between 400 and 500 mm whilst maintaining the exceptional strength of the standard boom. The ideal choice for re-handling duties which include vehicle loading and stockpiling work.

In applications that require high visibility and self-levelling capability using special attachments the tool carrier linkage is the best choice and comes as standard when ordering with the hydraulic quick coupler. This version is available on the following models W110D, W130D and W170D.

Have there been any improvements in maintenance and servicing?

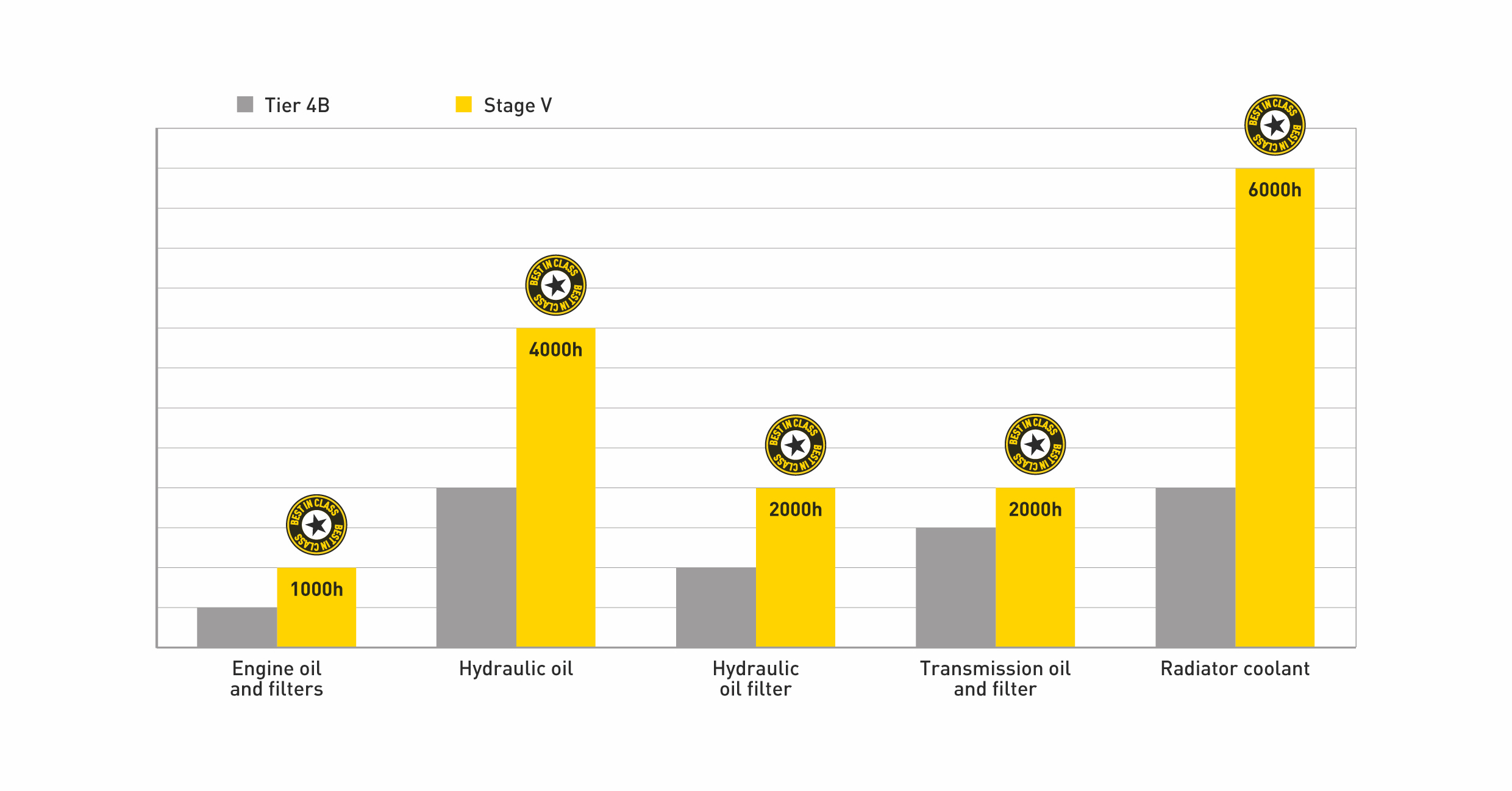

New Holland knows how vital a wheel loader can be to your business and that it can accumulate a high number of hours in a short period of time. In response to this we have doubled the engine service intervals from 500 to 1,000 hours as well as increasing the service levels of other fluids and filters.

You can save up to 20 per cent on maintenance costs, a significant saving over the whole life of the machine. When combined with the fuel saving benefits of the new Smart engine work mode, D Series wheel loaders guarantee a low total cost and keep you working for longer.