After his summer recess he’s back. Some say he likes nothing more than grading and shaping, others that backfilling and compaction are where he’s at. All we know is that we call him The Dig. This month he goes all backhoe.

The new K4 series backhoes were among a whole raft of new generation machines exhibited by Hidromek during the last Bauma two years ago. To see what all the fuss was about, we managed to get hands on with a demonstration model, the 9240kg HMK102B Supra K4 to be precise.

When the machine rolled out of the shed into some much welcome sunshine, my first impression was of a stylish thing of beauty. I have to say Hidromek’s talented in-house design team have done a fantastic job with this backhoe, aesthetically the sloping bonnet and front grill design look especially good, while the red grab handles and all black wheels just appear to give the machine a dominating style.

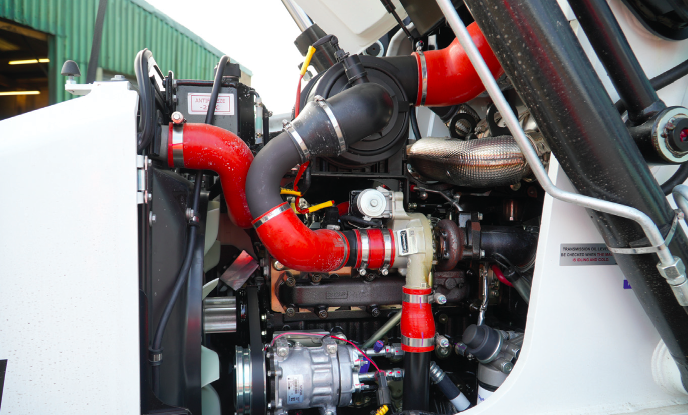

We took a look around the machine before taking it for a spin. Popping the large bonnet, it raises up effortlessly assisted by two hydraulic gas struts, allowing access to the Stage V emissions compliant, 4-cylinder Perkins 904JE36TA water cooled, turbocharged diesel engine, which offers an impressive power output rating of 74.4kW (100hp) at 2200rpm.

Easy to remove side panels allow greater access for regular servicing work. It’s tightly compacted inside but oil, fuel and air filters are all well located and accessible when needed.

Easy to remove side panels allow greater access for regular servicing work. It’s tightly compacted inside but oil, fuel and air filters are all well located and accessible when needed.

The front grill is also easily removed for access to the cooling packs, which in turn can be tilted outwards for ease of cleaning any debris build-up. A hefty looking bumper/counterweight is located below the grill for added protection of the cooling system components.

Having checked the engine out I appreciated the cloth strap attached to the bonnet which allows you to pull down on it for easy closure, a nice little touch. At the front business end, the machine is fitted with a 4-in-1 multi-purpose bucket which has a load capacity of 1.1m3, bucket mounted flip over forks come as standard, a handy feature of course, but so often a thorn in the side for any backhoe loader operator on a busy site!

Nice sturdy steps are provided on the 70- litre hydraulic oil tank for access up into the cab, with the lower ones painted red being able to fold upwards to prevent any damage from impact with materials. On the nearside just above the step a handy tool box panel opens up to reveal the optional electric refuelling pump and pipework, for filling up the 140-litre fuel tank. The fuel tank itself is situated on the offside as is the 15-litre AdBlue tank with its familiar blue cap. I assume the refuelling pump features an auto cut off when the maximum fill point is reached if you are stood on the pump side of the machine when fuelling up.

While other tyre options are available on request, this machine was sitting on 16/70-20 12 fronts and 16.9-28 14 rear tyres. We felt it could benefit from slightly larger tyres on the rear end. Well-proven axles are supplied by blue chip German manufacturer ZF.

More work, less fuel

More work, less fuel

At the rear business end the machine features rubber pads on the jack legs to prevent damage to paved surfaces. This top spec SUPRA model also featured the ‘Powerslide’ side shift function enabling movement of the boom infinitely from left to right and back by the flick of a switch in the cab, such a useful feature on sites where it’s not always possible to push the boom across using the bucket and boom in the traditional way. Another nice feature is the auto boom lock device once again via a switch in the cab for when roading the machine long distances.

Rexroth safety check valves are fitted as standard on the boom and dipper arm to adhere to health and safety regulations, and for the operator’s peace of mind during lifting operations.

The kingpost, boom and extendable dipper arm looked solid and well built, and the black paintwork really sets it off, also preventing sun glare for the operator during the hot summer months.

The machine features the well proven Bosch Rexroth closed type hydraulic system with a variable displacement piston type pump, renewable flowsharing and valves with regeneration. Hidromek suggests that the K4 series backhoe loaders are 20% faster and up to 3% more efficient, producing more work with less fuel than previous models thanks to improvements in cylinder design.

Climbing into the ROPS and FOPS-approved cab, one cannot fail to be impressed with the spacious interior, in line with many manufacturers, Hidromek claims it to be the largest cab interior volume in its class, I would not dispute that there is plenty of room, but in my honest opinion, it’s on a par with most of the other competitors in the BHL sector these days. As the SUPRA is the top spec model there are lots of additional switches and functions inside the cab, most of them are located on the console on the operators right when facing forward, it can feel slightly daunting until you have spent a bit of time in the seat using the various functions and becoming accustomed to what they all do.

You have to say, Hidromek’s design team have done a wonderful job with the cab appointments, everything is nicely laid out and falls to hand easily, I especially liked the automatic stabilizer controls that are centrally mounted on the offside control console, making them really easy to use whether facing forwards or to the rear. No less than two banks of multi-function rocker switches are provided, covering such things as working lights, windscreen wiper/wash, electronic hand brake, boom lock, and even joystick pattern selection to name a few.

Fans of the morning brew will be delighted to find not one, but two cup holders mounted to the front and rear. The cab also features two full colour information screens, with the smaller front screen mounted on the righthand cab pillar, while the larger rear screen is featured on the console to the operators left when facing the backhoe.

Stress-free experience

The machine is fitted with Hidromek’s Operator Interface (Opera) and via the rear screen the operator can access a whole host of features, such as oil flows for specific attachments, data on operating hours and machine status, maintenance schedules, language selection and Bluetooth radio control. The joysticks are integrated into the seat, to enable a comfortable and stress-free operator experience whether working with the front loader or the backhoe. When using the front loader for longer periods the lefthand joystick console can be released and tilted outwards to allow more room in the seat. That left-hand console also features a shifter button allowing the operator to control cab, one cannot fail to be impressed with the spacious interior, in line with many manufacturers, Hidromek claims it to be the largest cab interior volume in its class, I would not dispute that there is plenty of room, but in my honest opinion, it’s on a par with most of the other competitors in the BHL sector these days.

As the SUPRA is the top spec model there are lots of additional switches and functions inside the cab, most of them are located on the console on the operators right when facing forward, it can feel slightly daunting until you have spent a bit of time in the seat using the various functions and becoming accustomed to what they all do.

You have to say, Hidromek’s design team have done a wonderful job with the cab appointments, everything is nicely laid out and falls to hand easily, I especially liked the automatic stabilizer controls that are centrally mounted on the offside control console, making them really easy to use whether facing forwards or to the rear. No less than two banks of multi-function rocker switches are provided, covering such things as working lights, windscreen wiper/wash, electronic hand brake, boom lock, and even joystick pattern selection to name a few.

Fans of the morning brew will be delighted to find not one, but two cup holders mounted to the front and rear. The cab also features two full colour information screens, with the smaller front screen mounted on the righthand cab pillar, while the larger rear screen is featured on the console to the operators left when facing the backhoe.

Heaps of praise

Heaps of praise

Heaped full buckets were achieved with ease, and the machine which has a rear frame width of 2292mm, felt well balanced even with the bucketful raised to the maximum tipping height during the discharge, I found it to be a nice piece of kit to drive from a front loader perspective, but now it was time to try out the backhoe.

Spinning around in the seat, I was instantly impressed with the aforementioned autotilt steering wheel feature, a great idea and one less thing to have to worry about when running a backhoe loader, which can only be a good thing. Once turned around, I reached across to my left to deploy the automatic stabilizer function, I have no idea how it works, but they just set themselves up on the level.

With the flick of a switch the backhoe becomes live. Digging and piling the planings up on the heap, I was pleasantly surprised with the smoothness in operation, both in grading and digging applications. All functions worked in harmony with no lag when using 3 or 4 functions at once, most notably when grading in towards the machine whilst bringing in the extending dipper, raising the boom and slewing, it was all so super smooth!

The benefit of the machine being fitted with the powerslide backhoe was very evident, as I was able to slide it across to gain better visibility of the job in hand without the need to be peering around the boom to see, all achieved with the flick of a switch which was great. The machine has a maximum dig depth of 4409mm with standard arm, 5627mm with telescopic dipper extended, reach at ground level is 6845mm standard arm, and 8183mm fully extended.

From my perspective, overall, I was very impressed with this well-built and stylish Turkish contender, the earlier models were good, but with the K4 range they have just got a whole lot better.