It might be winter, but nothing stops him. Some say he has hydraulic fluid in his veins, others that he likes a bit of Adblue in his coffee. All we know is that we call him The Dig. This month he tackles a Takeuchi.

The market for legally towable mini excavators continues to be an important sector for manufacturers and contractors alike and the choice for end users continues to expand at a pace. Takeuchi’s latest addition to its 3-Series mini excavator line-up is the two-tonne class TB320, which is described by the manufacturer as a combination of mini excavator and a tool carrier supplied with a high-spec configuration. The TB320, which made its first public UK appearance during Hillhead in July, slots into the range between the ever popular 1.9 tonne TB219 and the 2.5-tonne TB225 and is sure to appeal to owner/operators in particular.

CPN was given access to one of the first examples to be sold into the UK market and travelled to Hereford for a “hands-on” experience.

Taking a walk around the new machine, and it features all the new styling that we have become accustomed to with the 3-Series models, somehow softer and more appealing to the eye, with more rounded edges than the previously angular look of the 2-Series models. The machine can be supplied with either a canopy, or in this instance the fully heated cab version.

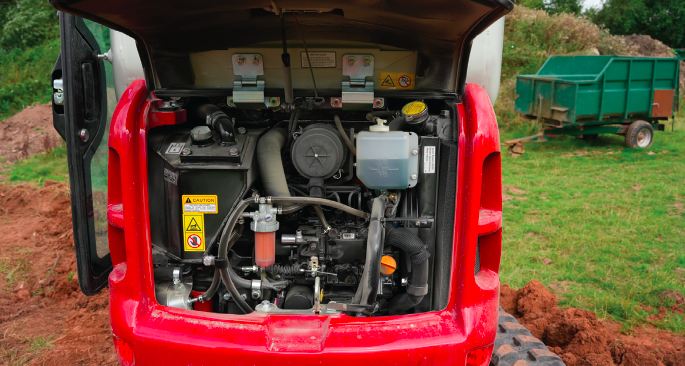

Engine bay

Popping the all-steel rear bonnet, which is assisted in raising by a gas strut, and we discover the popular EU Stage V emissions compliant, 3-cylinder Yanmar 3TNV70 diesel engine which offers a power output rating of 19kW (25.48hp) @2500rpm, with a rated maximum torque of 52.7Nm. There is a lot under the bonnet, but very neatly packaged for good access including the hydraulic oil tank and filler point, diesel, air and engine oil filters, radiator cap and associated expansion bottle, and of course the dipstick, all of which are very easy to reach for daily and routine maintenance. A sight tube gauge for the hydraulic oil level is provided within the rear nearside panel.

Round the corner on the offside rear, a panel door opens outwards to reveal the cooling pack for cleaning and a primary diesel filter/water separator again, easy to reach. Further along and a small door opens out to reveal the diesel tank filler point, this also features a secondary fuel gauge so you can monitor the fuel level status when filling up, a useful feature that can prevent overfilling and spillages.

Down below we find a dedicated storage place for the grease gun, which is ideal, as no self-respecting operator wants to be carrying a dirty grease gun in the cab. I was wondering where the battery was, but following further investigation, I discovered it is located in the cab, below the seat in the lockable opening compartment.

The machine also features the extending/retractable undercarriage which when fully retracted gives the machine a total width of 980mm, which is ideal for negotiating narrow gateways and the like, but when extended fully out the footprint is 1370mm, which when combined with the longer than average in this class track length of 1570mm, offers a stable and sure-footed working platform. Naturally the dozer blade features extension wings which are simply attached by easy to fit pins so that the blade matches the overall track width.

Standard rubber tracks are 230mm wide and the three lower track rollers are triple flange designed, which improve the ride and help to retain the tracks in position to prevent de-tracking. At the business end the TB320 loses out slightly compared to the TB219 in terms of overall dig depth and reach at ground level, with a maximum dig depth of 2,370mm and a maximum reach at ground level of 4,035mm, with the latter achieving 2,520mm and 4,175mm respectively. However, this machine, which has an impressive 40l/min oil flow rate, has been designed specifically as a tool carrier, for those who want to run those oil-hungry high flow attachments, such as flail mowers, mulchers, augers and the increasingly popular tiltrotators that in recent times have become the musthave accessory for groundworkers and landscaping contractors.

Standard rubber tracks are 230mm wide and the three lower track rollers are triple flange designed, which improve the ride and help to retain the tracks in position to prevent de-tracking. At the business end the TB320 loses out slightly compared to the TB219 in terms of overall dig depth and reach at ground level, with a maximum dig depth of 2,370mm and a maximum reach at ground level of 4,035mm, with the latter achieving 2,520mm and 4,175mm respectively. However, this machine, which has an impressive 40l/min oil flow rate, has been designed specifically as a tool carrier, for those who want to run those oil-hungry high flow attachments, such as flail mowers, mulchers, augers and the increasingly popular tiltrotators that in recent times have become the musthave accessory for groundworkers and landscaping contractors.

To facilitate this the TB320 comes as standard with proportional control on auxiliaries 1 and 2, with the 3rd auxiliary being pre-piped for a low-pressure quick coupler. In addition, a 4th aux line can be specified as a factory fit option.

Changing from single hydraulic flow to dual flow is an easy process, with the fitment of a simple lever switch at the front of the machine just below the lower cab window The machine also benefits from the main boom lift ram being mounted behind the said boom, which eliminates the risk of accidental damage by impact from a bucket tooth or attachment. This particular machine has been fitted with a Hill Tefra tilting hitch which does alter the geometry a bit, as the build height is quite significant.

The machine also features a heavier counterweight which comes in handy when working with heavy attachments and even offers benefits in stability with the tilting coupler fitted on this example.

Lighting up time

Lighting up time

With the dark winter nights now with us, it’s good to see that Scandinavian style LED working lights are provided as standard, two on the cab roof and one on the boom, additional lights can be specified from your dealer at time of order for those who require even more illumination.

Climbing into the cab and we notice the familiar automotive design and styling that we have come to expect from the 3-Series, starting with the comfortable seat emblazoned with the distinctive Takeuchi lettering on the backrest, this machine was so new it still had the plastic seat coverings intact!

I love the simplicity of the interior on the Takeuchi, on the right-hand side there are just a couple of rocker switches, for wiper/screen wash and the fan switch for heat/cool air supply, there is no air-conditioning option on this model, but a valve switch is provided in the cab to turn off the supply of hot water from the cooling system during summer months.

Double sliding windows are provided on the offside for the fresh air fans, and the front screen raises up in the traditional manner for storage in the cab roof, so plenty of options for air supply and of course communication with any ground crew.

The dozer blade lever is also situated in the familiar spot on the offside to the right of the arm rest, and a good old traditional manual throttle lever is provided behind it. The allimportant in cab radio is a standard fitment providing MW/FM frequencies and is also USB and Bluetooth compatible so you can pair your mobile phone to it.

To the offside rear of the cab, we find that other staple addition, the cup holder, and a decent sized screen wash bottle. To the front and we get the familiar Takeuchi full colour multi-function display monitor which provides all the feedback the operator needs to know such as fluid temperatures, fuel levels, hours worked and other warning lights.

The floor is a clean-cut affair, and easy to sweep out at the end of a shift, with just the left-right rocker foot pedal for the offset boom located on the far right-hand side, a footrest is provided on the left-hand side. Traditional T-Bar track levers are provided, but I noticed in this instance the usual button for the two-speed tracking isn’t on the right-hand track lever as we are used to, but is instead replaced by a round dump pedal on the floor operated by the heel of your boot.

I was invited to spend some time in the seat of the new machine, something I always relish especially when it’s red and grey. I was given the key, which coincidentally is the TSS (Takeuchi Security System) immobiliser key that comes as standard, and with a flick of the switch the machine came to life.

I was invited to spend some time in the seat of the new machine, something I always relish especially when it’s red and grey. I was given the key, which coincidentally is the TSS (Takeuchi Security System) immobiliser key that comes as standard, and with a flick of the switch the machine came to life.

A little warm up followed as I surveyed my surroundings, then lowering the isolation lever on the left-hand joystick console I was ready to work. Cranking up the trusty hand throttle I was greeted by the gentle thrum of the Yanmar powerpack. I tug on the right-hand joystick and we were off, no fancy or over complicated work modes or anything to ponder over, just get straight to work. A pile of soil was made available which had overgrown with grass, so I set about de-vegging.

As we have come to expect from the Takeuchi machines, it was super smooth on the hydraulics and a delight to operate. However, it was initially hard to break into the ground which I put down to the extra build height on the Hill tilt hitch, that’s a compromise with using those couplers, but the benefits would far outweigh any disadvantages in my opinion, and once I got the soil loosened up it was a lot easier.

Having said that I would imagine loading a high sided truck could be tricky with the Hill coupler too as the geometry wouldn’t help with soil retention in the bucket at the maximum dump height of 2725mm. The machine had plenty of grunt while using the dozer blade as I set about making a level platform on top of the heap having removed the grass, the longer track frame was a real benefit in terms of stability and keeping the tracks on the ground. Even with the weight of the tilt hitch the machine behaved itself even with a full bucket throughout the full arc of movements, even at full stretch with a bucketful which surprised me a lot.

The offset boom arrangement enables 78o of movement to the left and 49o to the right while the visibility in all directions is excellent. With a slew speed of 9.5rpm this 2-tonne is lively enough and with a top travel speed of 4.5km/h it doesn’t hang around, the whole machine was majestic in operation as we have come to expect from these top-quality Japanese-built machines. I enjoyed my time on this little powerhouse, which is sure to appeal to owner operators and specialist end users alike.