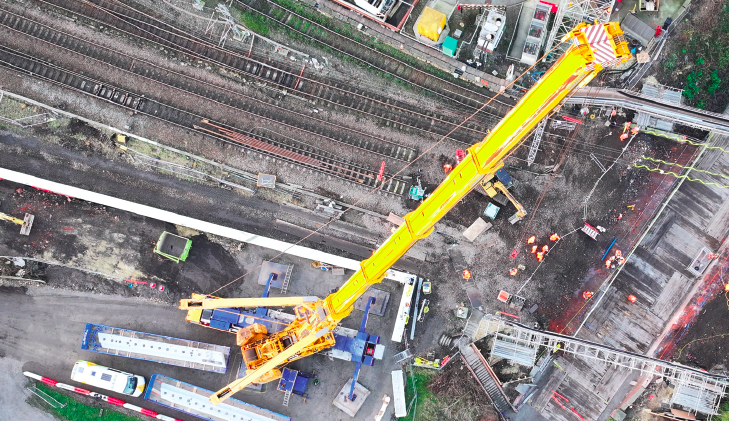

Replacing a railway bridge is no small feat, but the Transpennine Route Upgrade (TRU) East Alliance, supported by Mammoet, completed the operation at Osmondthorpe Lane, Leeds, with exceptional speed over the holiday period. A 100-strong team of TRU engineers, working with partners Network Rail, Murphy, Systra, VolkerRail, and Siemens, ensured the success of this complex project.

Central to the operation were two selfpropelled modular transporters (SPMTs), compact platform vehicles designed for transporting heavy loads with millimetre precision. Delivered to the site in sections, the units were configured with 128 wheels and operated as a single vehicle by Mammoet. The SPMTs consist of modules with 4, 5, 6, or 8 axle lines, each capable of carrying up to 44 tonnes per axle. With their modular design, the units can be connected side-by-side or head-to-tail to create large “platforms on wheels.”

These machines excel in manoeuvrability, offering 360o steering and the ability to perform carousel or sideways movements—ideal for the restricted site at Osmondthorpe Lane. Their hydraulically adjustable deck height, with a range of up to 60cm, allowed the precise vertical positioning of the bridge deck as it was moved from a temporary compound to its final location.

“These transporters demonstrate unparalleled efficiency and precision,” said a Mammoet spokesperson. “Their adaptability allows us to move large structures swiftly and safely, which was instrumental in ensuring the project’s success.”

The work was part of the multi-billion-pound TRU, a comprehensive upgrade aiming to deliver faster, greener, and more reliable train journeys between Manchester, Huddersfield, Leeds, and York. TRU improvements include fully electrifying the 70-mile route, enabling six fast services per hour between Leeds and Manchester, and installing cutting-edge digital signalling.

Andy Stocks, East of Leeds Alliance director for TRU, praised the collaborative effort: “Our engineers worked tirelessly to deliver this milestone. Replacing the old bridge deck with a stronger structure was a complex task, but the speed and professionalism demonstrated reflect our commitment to delivering high-quality upgrades.”

Following the bridge replacement, engineers laid new tracks, installed over 270 tonnes of ballast, and reopened the railway on schedule. The precision of the SPMTs ensured that the bridge was positioned quickly, allowing the team to complete all associated works on time.

The Osmondthorpe Lane project was one of several significant upgrades completed during the Christmas and New Year period. At Mirfield, a section of Station Road railway bridge was replaced to support a new accessible station entrance, while foundations for overhead line equipment were installed at Church Fenton near York to facilitate future electrification.

Meanwhile, near Miles Platting in Manchester, vital track points were renewed to improve train movements across the network. With its fast-tracked timeline and reliance on state-of-the-art technology, the Osmondthorpe Lane project underscores how innovations like SPMTs are revolutionizing construction methods in the rail sector.

Two self-propelled modular transporters (SPMTs) from Mammoet enabled a 200-tonne railway bridge replacement at Osmondthorpe Lane, Leeds, to be completed in record time. This key milestone in the Transpennine Route Upgrade showcases cutting-edge engineering and teamwork.