Summer’s here and he’s ready for some sun. Some say he’s a stickler for detail when reviewing machines, others that he leaves no stone unturned. All we know is that we call him The Dig. This month he gets back on track with Cat’s 265.

Such is the demand for the highly versatile compact tracked loader, the global CTL market was valued at $27.3bn in 2023 and is predicted to register a rise in value by over 5% annually up to 2032.

It’s not hard to see why either, as in the right hands these machines, which are able to run an infinitely wide range of static and hydraulically powered attachments, can turn out a lot of work across a wide range of industry sectors, and offer a far more comfortable operating experience than a traditional wheeled skid steer variant.

So it was with great delight that we accepted an invitation to Finning’s headquarters in Cannock, Staffordshire to undertake a test drive of the latest Caterpillar next generation 265 CTL model which, in line with its other tracked siblings, is built in Caterpillar’s North American facility in Sandford, North Carolina.

Muscle flexing

Muscle flexing

The 265 which along with the 255 was officially revealed towards the end of 2023, has an operating weight of 4759 kg, and is effectively the replacement for the previous 279 D3 and 289 D3 models.

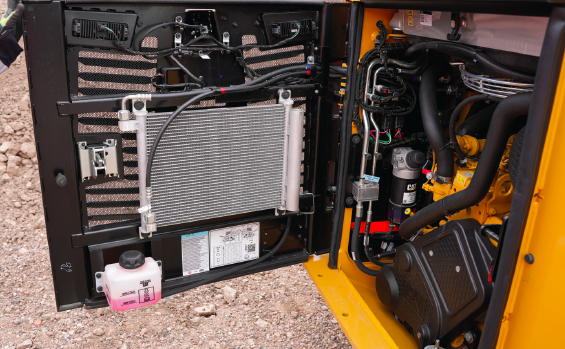

However, in terms of breakout force and torque power it’s been increased in this size class to make it comparable to the previous larger 299 D3 model. To get acquainted with the new machine I was given a walk-around tour by Finning UK & Ireland’s BCP (Building Construction Products) product manager Helen Day. Popping the heavy-duty metal rear door reveals access to the Stage V emissions compliant Cat C2.8TA four-cylinder, turbo after-cooled diesel engine, which produces a net power output rating of 54.9kw (74hp) between @2200-2400 rpm and a maximum torque of 380Nm @1360 rpm.

The wide opening facilitates ease of access for daily checks and routine maintenance during service intervals, with dipstick, oil, fuel and air filters and coolant expansion bottle all easy to hand. In addition, the battery and electrical isolation switch are nicely located at the lower righthand side of the engine bay.

Nice undercarriage

The roof of the engine bay can also be lifted up or removed easily if preferred to allow for debris cleaning of the main engine cooling pack, mounted above the efficient on demand variable speed hydraulic cooling fan.

Walking around to the side of the machine we notice that there has been a complete change in the undercarriage design, in that it now features a one-piece torsion suspension undercarriage bar system. With an overall track length of 2126mm this, especially if combined with the optional speed sensitive ride control system, is said to offer improved stability and a much smoother ride in the cab. That is a bonus if operating on rough ground, while also ensuring better retention of the load in the bucket, something that I really got to appreciate during my time in the seat.

Hail that cab

Continuing the ground up re-design the operator station is completely new. Access is via the familiar route, stepping up over the bucket or attachment via a couple of antislip steps, with the bucket attached on this example, a third anti-slip step is provided on the top left-hand side while a sturdy grab handle on the left-hand side of the cab further assists with access and egress. The access is a lot easier on these models as you are not having to climb over the loader arms cross member that was the design on the outgoing D3 model, it just has a much lower opening and accessible feel to it, and when seated in the cab it further enhances the forward visibility too.

Ensconced in the comfortable, fully adjustable, heated air suspension seat, I immediately noticed the roomy feel inside this ROPS and FOPS one-piece, sealed and pressurised cabin. According to Caterpillar this interior space has been increased by 22% and looking around I have no reason to doubt that statistic. Towards the rear of the cabin there is a decent sized shelf where you could easily fit a large lunch bag or even a coolbox, on this occasion it was a nice place to store my hard hat.

What’s on the menu?

In terms of width, it’s very accommodating and I didn’t get that often claustrophobic feeling that used to be common inside these type of machines from the various stables. The joystick consoles can be raised or lowered to enable the operator to find that perfect operating position for their size.

The cab is well appointed with the new 20.3cm (8in) advanced touchscreen monitor, which is exactly the same monitor that Cat fits in its mini excavators. This screen is superb and offers a crystal-clear view of all the functions that can be accessed via the menu. The top portion of the monitor hosts warning lights and indication dials for fuel level and engine temperature, while the lower portion of the monitor provides the operator with other machine status feedback, hours worked, time etc.

Below the screen there are six selection buttons for such things as camera view, track speed, audible alarm, radio mute and the main menu where you can find a whole host of settings including auxiliary hydraulic flow settings for attachments. When selecting reverse the monitor automatically becomes the rear-view camera, offering a superb view of the area behind the machine when backing up. The monitor can be navigated by using the advanced joystick controls, which means when you are operating, you don’t even need to remove your hands from the joysticks, enabling you to do such things as adjusting the radio volume, activating creep speed and one-button smart attachment control to name a few.

Heating and air-conditioning controls are mounted in the roof of the cabin to the operator’s upper right-hand side, with hot or cold air being distributed via fully adjustable vents in the cabin. For those who like the fresh air, and don’t mind a bit of dust coming in, the side windows on both sides can be slid open fore and aft as required, with the usual mesh protection to keep the operator safely protected from the loader arms.

Go with the flow

Go with the flow

As previously mentioned, these machines are increasingly used to power hydraulic attachments such as flail mowers and planers. To facilitate this, these machines feature three levels of auxiliary hydraulic performance consisting of standard flow, high flow, and the high flow XPS option for those really oil hungry attachments. In standard flow you get a hydraulic pressure of 3,500 psi, with a hydraulic oil flow of 86 l/min (23 gal/min), whilst in the high flow XPS setting it puts out a whopping 4,061 psi with an oil flow of 129 l/min (34 gal/min). The machine also features a class leading lift height of 3354mm (132in) at bucket pin height, that’s some four inches more than its closest competitor the Bobcat T76. Maximum overall height with arms raised and bucket curled right back is 4173mm (164.3 in). I was keen to get in the seat to see what all the fuss was about. Once I punched in the four-digit code on the touch screen and connected the large orange lap belt, which is required to enable you to start the machine, I flicked the ignition key and the Cat 4-cylinder power pack sprang into life, with a gentle thrum.

The machine features a foot throttle pedal, but on these machines, I much prefer to set the engine speed using the rotary dial which is mounted on the right-hand side front pillar just below the ignition key.

I cranked up the speed to around 3/4 revs and was pleasantly surprised by how quiet it was in the cab; apparently it’s rated at 80dB(A) inside, while outside the cab the noise level is rated at 103dB(A).

Lowering the additional safety bar across my lap from the right-hand side, and with a push on the red parking button on the dash, I was ready to set off. The controls are standard ISO configuration for these machines, with the boom lift and bucket tilt on the right-had joystick, whilst the forward-reverse and steering is accomplished using the left-hand joystick, all extremely intuitive and simple to use.

Heaps of praise

For the purpose of this test drive, I was just digging from the face of the pile of stone and hardcore travelling with it to the top and tipping it back down the face, a bit of a job creation assignment, but it did give me the chance to get a real feel for this new model. In the dig this machine punched well above its weight and it certainly had some grunt as I powered into the heap, curling up the bucket to get a full load. Apparently, this new model gives you a massive 43% more torque compared to the old 289 D3 model, and you really feel that extra power as you push into the heap, which is super impressive.

The view to the cutting edge of the bucket is on a par with the well-known white liveried brand if not better I would have to say. Powering up the slope to tip the load I never once felt the need to drop down to the one speed option, and in its two-speed option you get a lively top speed of 13 km/h (8.1 mph), not that I could achieve that within the confines of the demo area, but we did get some decent speed going.

Sitting on 450mm rubber tracks, (other options are available) and with an overall width of 1925mm (75.8in) the machine which has an incredibly low centre of gravity, feels unstoppable and well balanced at all times. I got the feeling that you could work on some pretty extreme slopes in complete safety as it felt entirely planted during this test drive.

In terms of operator comfort, I could not find any faults whatsoever, and I am always looking to offer some constructive criticism, but it wasn’t to be on this test drive. The seat was a very nice place to spend a shift, the controls were light and easy to use, and the visibility was excellent in all directions, even allowing for the heavy duty and beefy looking loader arms to contend with, when looking out the side windows.

What I also enjoy with CTLs is that you are not constantly being bounced about as you often are with the wheeled variants; in these tracked versions, travel is smooth and turning is precise, controlled and powerful.

My concluding thoughts were of a wellbuilt and super powerful CTL for its size class, and a machine that left a lasting impression on me, I genuinely had a lot of fun running it on the day.

For more information on Caterpillar machines