“Compressed air could be the next thing to revolutionise the construction industry in its drive to reduce energy costs, maximise profits and work towards improving environmental concerns.”

Traditional air compressors have been widely used across many applications in construction, but they are not without their problems. Regardless of usage, all of these applications face a common challenge, they must be both reliable and durable to cope with on-site conditions, yet quiet enough to maintain a responsible working environment.

On-site noise is not only a real concern when it comes to the welfare of employees, but can also be a criminal offence. The lawyers Pinsent Mason have reported a significant rise in Section 60 Notices, a procedure in place to restrict the amount of noise and vibration caused from construction sites. Construction managers who fail to minimise noise caused by machinery is a criminal offence and can lead to a fine of up to £20,000.

Despite playing an integral part of the industry few people realise that compressors have not benefitted from a step change in over 80 years and as a result are inefficient and noisy. In fact WRAP, the Waste and Resource Action Programme, revealed that for every Watt of electricity consumed in a traditional compressor used in construction, 90 per cent is typically wasted. Every time your compressor rattles or vibrates consider the amount of significant energy is being lost.

A key factor for energy loss within construction is the use of outdated technology. In a traditional rotary compressor, the shape of the internal surfaces can give rise to high internal leakage, and all leakage represents wasted energy.

That’s where Lontra’s Blade Compressor comes in; it is the first big change in design to disrupt industry since the screw compressor design back in 1935. By way virtue of its unique design, it offers significant energy savings. Already deployed in the wastewater industry, the technology has proven to be over 21 per cent more efficient than traditional compressors, which is significant given most companies try to optimise for gains of just 1 – 2 per cent.

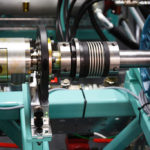

Unlike traditional compressors, the Lontra Blade Compressor is distinguished by its geometry. It’s broad sealing areas allow for excellent efficiency, operating at relatively low rotational speed. As the piston or blade rotates, it draws in air behind it in the same way as the piston dropping down in the cylinder.

As it gets back to the starting point, it has drawn in a complete volume of air behind it. Yet, unlike the traditional piston and cylinder that must stop and change direction, the blade passes through a disc and the volume of air that was trapped behind the blade is now in front.

In essence it is a piston compressor “wrapped around” so that it flows continuously. This means that it has an almost continuous cycle of drawing in air behind and compressing air in front, resulting in a smooth, efficient and reliable cycle.

One of the first companies in the UK to trial the Lontra Blade Compressor was Severn Trent Water, which has been using the technology since 2012.

The technology delivered energy savings verified by Severn Trent Water of 21 per cent with a potential £1.8m reduction in their annual energy costs for the business. Similar savings are also expected in other industries; particularly in pneumatic conveying applications where Lontra has received a large grant from the EU to take the technology to market.

That success within the wastewater industry highlights the potential of the technology in other industries and the innovation is gaining momentum across the engineering sector.

Since the Severn Trent Water trial global engineering group and Lontra’s first licensee, Sulzer, has installed Blade Compressor machines across Europe and their improved reliability has become a major selling point. Lontra and partners Shield Group are also building a substantial UK manufacturing facility dedicated to the production of the technology to serve a wide range of global sectors ranging from food and pharmaceutical production, to cement production and aggregate transport.

The first adopters of the Blade Compressor in the construction industry will be able to use either Lontra’s pneumatic conveying compressor, or the upcoming vacuum pump. As future Blade Compressor models are launched, this disruptive technology is also expected to enter the pneumatic tool and drill-air market.

As energy demand escalates across all aspects of our global society, energy costs rise and businesses face increased competition. The Blade Compressor has the potential to provide industry with a “triple win”, offering businesses significant opportunities for improved reliability, reduced energy use and the associated environmental gains.