Applications, regulations, treatments – there’s plenty to consider when understanding your pressure requirements.

1. Finding the ‘sweet spot’

Compressors must provide the right amount of pressure – or force – needed to complete the required process. Not too little, or too much. Too little pressure means pneumatic tools won’t work, whereas too much pressure can damage the equipment, waste energy, and raise operating costs.

2. Unique conditions

Every project is different, and not every application requires the same level of pressure. Geothermal projects, for example, require deep boreholes to be drilled into the earth, which can only be achieved by using compressors with a pressure output of 35 bar. Abrasive blasting projects, on the other hand, may only require 10 bar of pressure.

3. Setting the PACE

Those requiring varied pressure levels for different aspects of a project can benefit from using a medium compressor fitted with PACE, or large compressor with Air Expert. With our patented technologies, you can adjust pressure while the compressor automatically regulates flow. Operating handheld tools, then tackling a shotcrete application an hour later? No problem.

4. Raising the bar

In the drilling industry, there is heightened consumer demand for compressors that prioritise speed and efficiency. This demand can be met using high pressure compressors, such as the DrillAir – especially designed to maximise efficiency by drilling faster than ever before, and helping to save valuable time and costs.

5. Going with the flow

For sufficient pressure, you need consistent flow. A large air compressor, for example, takes the hammer downwards by applying a downward pressure, while the flow keeps it rotating. For optimal performance, the goal should be to supply an application with the proper air flow at the correct pressure, and treat the pair as inextricably linked.

6. Boosting your efforts

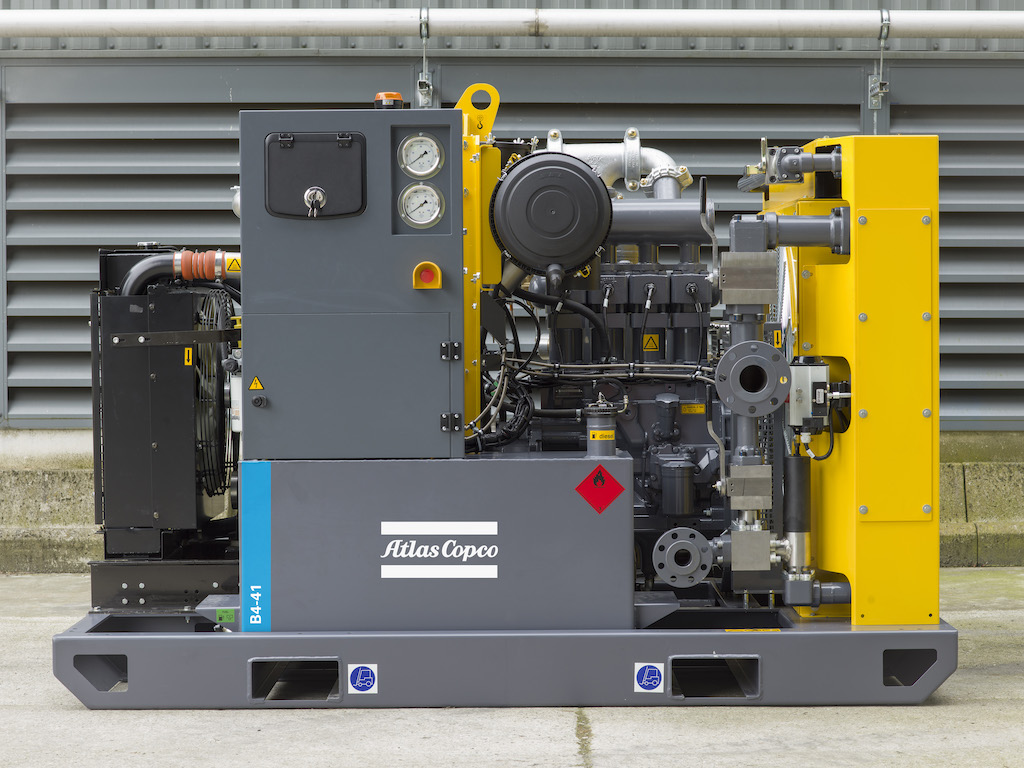

For projects that need pressure above 35 bar, boosters are available. Atlas Copco compressors come in oil-free or nitrogen variations, and can reach anywhere from 69 bar to a whopping 345. They have extensive pressure inlet / outlet, and flow capacity for a wide range of applications – even in the harshest and most demanding conditions.

7. VSD is key

Variable Speed Drive (VSD) compressors are a smart choice when demand for air varies, and allow for continuous flow rate regulation. VSD compressors can operate at very low delivery pressures while still maintaining the air system’s required minimum working pressure, and also deliver more consistent discharge pressure for all the compressed air applications throughout your facility.

8. Tried and tested

At Atlas Copco all new, updated, or repaired pressure containing systems are first put through a leak test, and then a strength test. The latter puts the compressor at 110% of the system’s maximum operating capacity, where it is kept under pressure in order to monitor integrity and safety. All components are also manufactured in line with the strict industry standard of pressure regulation – the European Pressure Directive.

9. Preserving quality

A holistic approach is needed to maintain pressure quality, as different components can negatively affect performance. Filters, dryers, and the compressor’s piping and valves all need to be considered and maintained appropriately in order to keep pressure working in tip-top shape.

10. A tailored outlook

Ultimately, a systematic approach should be taken to select a compressor in line with the needs of the application. When the role of pressure in a process is clearly defined, finding the system that will be the most profitable and efficient becomes simple.