Introducing CPN’s newest team member. Some say he brags about his bucket skills, others that he’s sharp with a blade. All we know is that we call him the Dig. This month he goes big with minis.

In 2021 a new era for Case began as parent company CNH Industrial acquired the privately-owned Italian manufacturer, Sampierana SpA, which has a long history of producing its own Eurocomach range of mini and midi excavators. The move effectively gave Case access to an in-house designed and manufactured range of compact excavators.

The company, thanks to its involvement with the Italians, now offers a range of 20 different mini excavator models from the 1-tonne CX12D up to the CX65D which competes in the 6-tonne class.

It is in the unique position of being able to offer no less than four mini excavator models featuring a two-piece-boom, including the smallest in-class TAB boom equipped CX20D 2-tonne model, up to the previously mentioned 6.5-tonne CX65D.

I’ve been keen to get my hands on one of these new models since they first started arriving in the UK, and fortunately I was invited down to my local dealers M&M Plant (Devon & Cornwall) Ltd, to spend some time in the seat of the 2.5-tonne offering, the CX25D.

I’ve been keen to get my hands on one of these new models since they first started arriving in the UK, and fortunately I was invited down to my local dealers M&M Plant (Devon & Cornwall) Ltd, to spend some time in the seat of the 2.5-tonne offering, the CX25D.

It’s probably fair comment to say that the old Hyundai inspired Case mini excavators were looking rather dated, so it’s great to see these eye-catching Italian-designed machines replacing them in the line-up. If we were talking cars then it would be like upgrading from a Kia Soul to a Ferrari Roma, such is the gulf in design aesthetics.

Of course, the CX25D is not the newest machine, we have been seeing it for a while now in its more traditional red Eurocomach plumage as the 25ZT model, but in the familiar Case tan livery and branding it takes on a whole new identity of its own and very smart it looks too!

With an operating weight of 2580kgs in its canopy variant, or 2710kgs with fully enclosed cab, these zero tail-swing machines are ideal for small groundworks contractors or jobbing builders and is easily transportable in-line with local towing regulations.

I took a walkaround this stylish 2.5-tonner. The machine has a number of unique features, the most notable being that when you open the rear engine bay panel, you notice that the tough plastic door also integrates the 26-litre fuel tank, which is very clever use of a space that would otherwise be wasted. It’s such a simple but effective idea, you wonder why nobody else has done it before. Additionally, just below the tank you find the fuel filter and water separator, which with the panel open, are super easy to work on when changing the filter or draining off water.

I took a walkaround this stylish 2.5-tonner. The machine has a number of unique features, the most notable being that when you open the rear engine bay panel, you notice that the tough plastic door also integrates the 26-litre fuel tank, which is very clever use of a space that would otherwise be wasted. It’s such a simple but effective idea, you wonder why nobody else has done it before. Additionally, just below the tank you find the fuel filter and water separator, which with the panel open, are super easy to work on when changing the filter or draining off water.

For those wishing to use heavy work attachments or fitting a tiltrotator, an additional counterweight can be specified, but will obviously negate the machines zero-tailswing capabilities slightly.

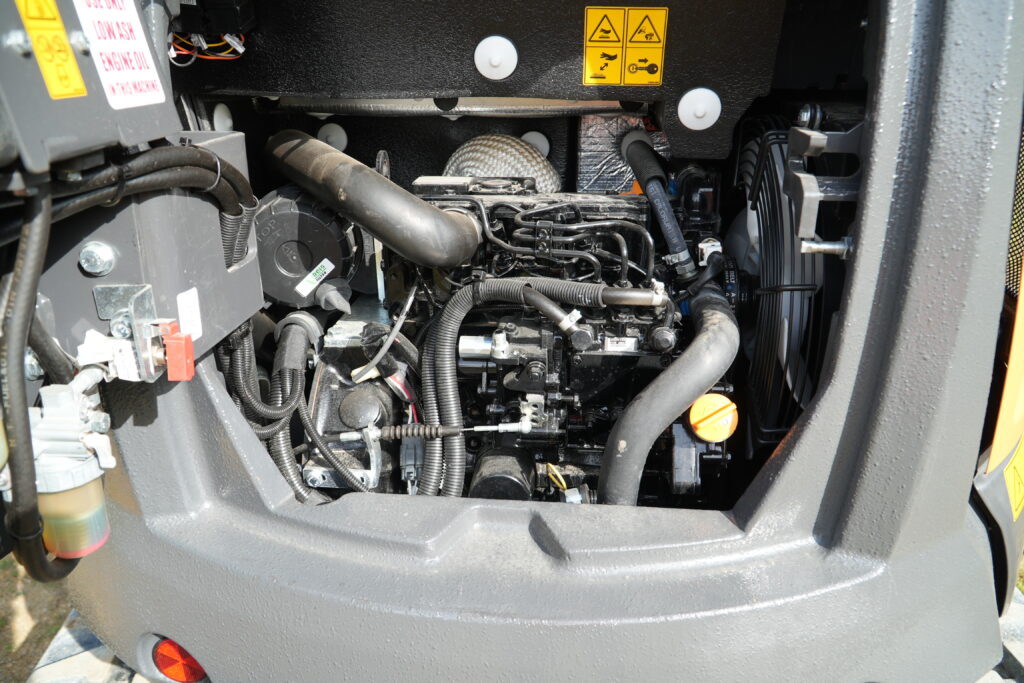

Nicely packed inside the bay is the almost industry standard, Stage V emissions compliant, 3-cylinder Yanmar 3TNV76 diesel engine, which produces a power output rating of 13.7kw (18.6hp) @2200 rpm. Access for daily checks and oil filter change is good as one would expect these days.

Wandering around to the offside of the machine, and a large top bonnet raises upwards, while a side panel is easily removed to gain access to the radiator, cooling pack, and expansion bottle. The plastic hydraulic oil tank which has a capacity of 26-litres, is also located under the bonnet but also forms the off-side front body work.

Below the hydraulic tank area, a lockable metal panel can be removed to gain access to the 12v battery, and the battery isolation switch. The battery looks like it could be a little tricky to remove, but I’m sure there is a practical method for doing so.

A similar lockable plate cover on the rear nearside allows access to hydraulic pipework and the Casappa hydraulic pump, hydraulic pressure testing ports are also located in this area.

The whole cab can be tilted by removing two large bolts and it has a support spring to assist with the weight, especially useful if you need to gain access to major components like the Eaton slew motor and the main hydraulic valve block, as well as the rear side of the engine.

With a long history of manufacturing them, it’s safe to say Sampierana know a thing or two about undercarriages and the one on the CX25D looks well-built coming as standard with 280mm wide rubber tracks and has a track length of 1997mm. Four bottom rollers are fitted and one top roller, overall track width is 1500mm, which is the same width as the blade and makes for a steady working platform. Track motors are supplied by Transmital.

At the business end, this machine featured the more UK favoured longer 1550mm dipper arm, which combined with the standard boom offers a maximum dig depth of 2900mm and a maximum dumping height of 3310mm and bucket breakout force of 2200daN. This unit was fitted with a Strickland fully automatic quick coupler.

The machine comes as standard with a boom ram guard, but I note that none of the other two rams feature rod protection guards. One single or double effect 45 – 210 bar auxiliary line comes as standard but a second and third can be added as an option.

And so, to the cab, popping the door, I was delighted to discover that when fully opened and retained, the door frame sits nicely in a recessed area, well out of the way to avoid any potential damage from accidental impacts. The rear rotation radius on this extremely compact machine is just 750mm.

Climbing into the cab, the door entrance is nice and wide to facilitate access and egress, this cabbed version features a cloth manual suspension seat, which features nice body hugging contours and makes for a nice comfortable driving position.

The cab on these D-Series models certainly has a more spacious feel to them compared to the outgoing C-Series models. The legroom on the floor is okay but a taller operator might struggle a bit. Folding travel pedals are provided which can give extra foot space when folded away.

I really liked the simplicity in this cab, with just a handful of rocker switches for the working lights, flashing beacon, windscreen wiper/wash and quick-coupler. On the right-hand side console, facing the operator a multi-function dial offers feedback on the machine’s fluid levels, temperature and other vital information.

I really liked the simplicity in this cab, with just a handful of rocker switches for the working lights, flashing beacon, windscreen wiper/wash and quick-coupler. On the right-hand side console, facing the operator a multi-function dial offers feedback on the machine’s fluid levels, temperature and other vital information.

To the rear of the console, I discover a good old fashioned style throttle lever, no electronic rotary dial in this machine, so less to go wrong. Talking of levers, I noticed one problem with the dozer lever, it is mounted so close to the side windows, that you cannot physically get your hand around it. Apparently, this issue had already been identified and a solution/modification is already being implemented on new machines.

I put the machine to work on some land adjacent to M&M’s depot at Kennards House near Launceston. Initially pressing the button, a little awkwardly on top of the dozer lever, I selected the tortoise track speed, offering me more torque on the climb up onto a heap of shillet material, to enable me to dig with a toothed digging bucket to get a feel for this machine.

Just for the record, track speed in tortoise is 2.6km/h while switching to the hare position offers you a top speed of 4.3km/h.

I was impressed with the machines digging power, as it certainly packed a punch, almost effortlessly in the dig and the feedback through the Rexroth servo-assisted joysticks was extremely positive, far superior to the feel on the levers on the old C-Series models. These new models definitely seem to be on another level.

I decided to swap buckets to do some grading and shaping work. The machine excelled itself in the grading department, silky smooth and precise with the movements. The machine is quite fast in operation and a slew speed of 11rpm is pretty much the standard for this size of mini excavator; I also like the off-set boom function being on an electro-proportional roller thumb control on the left-hand joystick, making it super easy to slew the upper-structure and slew the off-set at the same time.

Talking of the off-set with the CX25D you get 65o to the left and 62o to the right. Personally, I still long for a return to the days when manufacturers used to offer a full 90o to the left, like on the old Komatsu’s towards the end of the 1980’s and early 90’s, that combination was great for doing ditch cleaning work and the like offering great visibility to the job in hand, but for some reason, manufacturers don’t seem to offer it anymore.

Talking of the off-set with the CX25D you get 65o to the left and 62o to the right. Personally, I still long for a return to the days when manufacturers used to offer a full 90o to the left, like on the old Komatsu’s towards the end of the 1980’s and early 90’s, that combination was great for doing ditch cleaning work and the like offering great visibility to the job in hand, but for some reason, manufacturers don’t seem to offer it anymore.

This machine didn’t have any air-con fitted and on what was a very hot day, I decided to have both the door and front window open. There are three air vents located around the cab, but I opted for the natural fresh air approach on this occasion.

Overall, I walked away from this test drive feeling very impressed with these new Case machines, and I feel they will do very well in the marketplace. In addition, with the knowledge that even newer models like the CX75E coming down the line, I see a bright future for Case’s new and extended mini/midi excavator range.