Network Rail is committed to improving rail passenger safety and performance and their Infrastructure Projects (IP) Track Engineering and Innovation team has recently concentrated on improving processes and equipment to increase ‘right first time’ quality enabling ‘high-speed’ handbacks after track is replaced.

Over Christmas and the New Year, a number of ‘high-speed’ handbacks were achieved after line and ballast replacement.

Handing back the railway and immediately allowing train speeds of up to 125mph, following major plain line renewal works is a first for the modern railway.

The keys to achieving this across the full programme of track works are making sure new track is installed within its design tolerances, precision tamping of ballast enabling the track to be positioned accurately, and the completion of welding and de-stressing when sufficient access is available.

The IP Track Engineering and Innovation team, working in conjunction with the Network Rail’s Safety Technical and Engineering group, and with the principal contractors, has developed a number of advanced engineering techniques to assist high-speed handbacks.

Recent innovations has included excavation and dozing using an integrated Topcon 3D positioning and control system to position and grade the ballast to the design co-ordinates, which means the tamper doesn’t have to make large alignment lifts which undo the consolidation of the bottom ballast.

In addition, improved consolidation of the ballast has been achieved through dynamic Track Stabilisation (DTS).

In addition, improved consolidation of the ballast has been achieved through dynamic Track Stabilisation (DTS).

Use of the road/rail self-propelled single drum Bomag BW 213 BVC 4i, developed by Rexquote and operated by Trac Rail, to deliver the correct, uniform consolidation of the new replacement ballast has been a further development.

This enables measurement and recording of compaction in real-time by the Bomag, whilst placing the ballast to design has also been achieved, so that the tamper does not undo the work of the Bomag roller, all of which allows for a short period of traffic under a temporary speed restriction to gain consolidation before raising the speed to full line speed.

Other Advanced Engineering Techniques Include:

• Placing the track panels accurately to their design position using a total station or GPS, rather than placing them using a tape measure and expecting the tamper to make large adjustments in alignment.

• Making sure the constructed track position is measured accurately using total station or GPS so that accurate off-set files, against the actual design, can be generated for the tamper.

• Manual packing using hand held tampers on areas of track that cannot be tamped.

• Improved clamping systems

• Back hole drilling up to 80mph

• High Speed Clamping System up to 100mph

• Completion of welding and stressing of the rail to allow full line speed

The development work undertaken by Network Rail’s Infrastructure Projects (IP) Track Engineering and Innovation team is paying off with significant cost and time benefits as track installed to a higher quality has greater longevity, improved reliability, performs better and therefore has a lower whole life cost.

Their use of the latest excavation, dozing and compaction equipment with highly sophisticated integrated measurement and control systems proves that these systems can earn their place in real world applications.

The Bomag Vario was successfully deployed by Works Delivery Track North-East at Cramlington Station when 200 yards of track were replaced. The compaction force applied by the machine was managed on site, allowing it to successfully compact new ballast in a platform and adjacent to an overbridge sensitive to vibration.

Mick Harrison, On-Track Plant Specialist, commented after the Bomag was used at Cramlington: “The bed quality was excellent.

“We found a 20-25mm drop, on average, in ballast height following the final pass of the Bomag. Subsequent measurement revealed that the track has settled by just 3 mm, showing a good track bed performance.”

Genie

Genie

Taunton based Rexquote is an acknowledged leader in converting construction equipment to have a road/rail capability. Their product range includes excavators, dump trucks, cranes and the Bomag roller featured.

More recently Rexquote has developed a range of on-rail access equipment for use by technicians working on overhead signalling infrastructure and power lines.

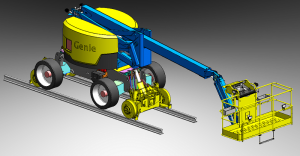

Hot off the press Rexquote is nearing completion of a new addition to their range of access equipment in the shape of a self-levelling Genie Z62/40 4-wheel drive Access Platform.

This innovative product is in the final stages of design using Rexquote’s sophisticated 3D CAD/CAM system. The prototype will be completed by Rexquote’s 35 strong workforce during March.

The Accessrailer 400kg, as it will be known, is a successor to the very popular Z60/34 which Rexquote has converted to a 300kg model for the railway since 2006.

The new 400kg model features 4-wheel hydraulic drive rail axles and new and unique fully automatic self-levelling system developed by Rexquote.

This will enable the machine to work on canted rail up to 200mm without loss of capacity whilst retaining the working envelope of the 300kg model that has proven so popular.

The machine’s basket has been uprated to legally carry three people and following completion of EN280 approval at the end of March the first unit will be out working on the UK’s rail infra-structure in April.

The Accessrailer will also feature an on-board modem with 3G data access to allow Rexquote staff to download data logs on behalf of the owner and to assist maintenance staff in the event of a problem arising.

This benefit has been welcomed widely in the 2 years since introduction on a number of models.