Under the theme of ‘Powered by Innovation’, Doosan Infracore Europe has announced a number of new developments that not only add to the company’s current Smart Solutions portfolio for the Doosan range of construction, quarry and mining equipment and but also give a preview of what will be coming from the company in the future.

They include a new strategic partnership with Palantir Technologies, an American big data unicorn (a term for a start-up company with a current valuation of US$1 billion or more). This is the first of its type in Korea and forms part of the company’s efforts to provide new products and services by converging ICT technologies such as big data and the Internet of Things (IOT).

The service programmes within Doosan Smart Solutions also aim to maximize operating efficiency by creating a smart work environment and as part of this, Doosan has launched a new mobile app for Apple and Android devices for its successful DoosanCONNECTTM fleet and asset management system, now covering over 70,000 of Doosan’s machines worldwide. Further support is provided by a package programme of regular maintenance and extended warranty designed by Doosan and carried out by the service teams at Doosan dealers.

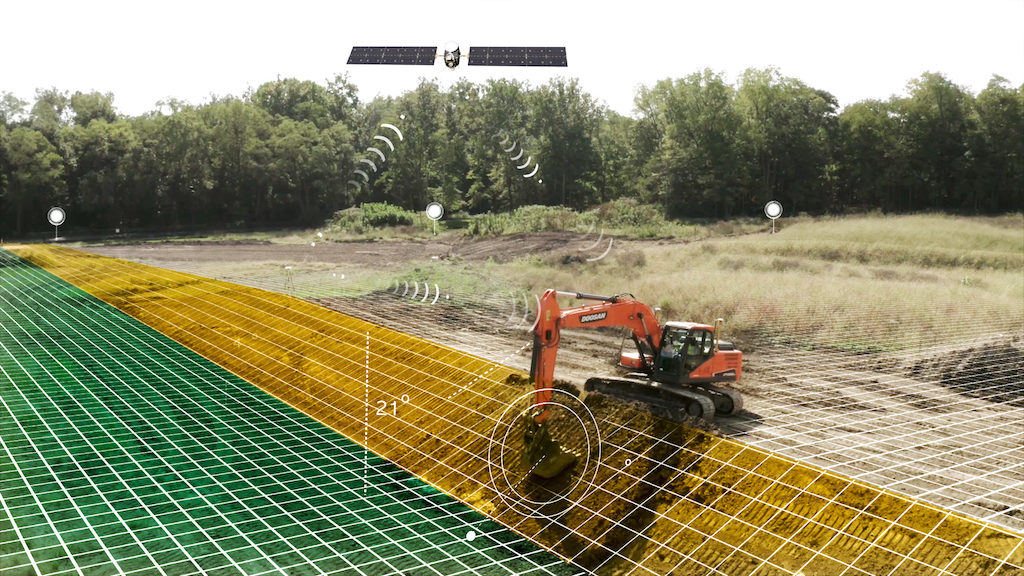

To meet increasing demand for the increased efficiency offered by machine guidance systems on excavators, Doosan Smart solutions is now offering new Leica, Trimble and Xsite Ready Kits for the Doosan wheeled and crawler excavators from 14 to 30 tonne. Doosan Smart Solutions already provides factory-installed options for the increased flexibility offered by SVAB/Steelwrist tiltrotator systems for the Doosan wheeled excavator range.

Giving us a glimpse of the future, Doosan provided an industry-first with a demonstration at Bauma 2019 of long distance remote control of machines using the new 5G telecommunications platform and previewed the company’s ConceptX, providing a complete suite of solutions for site automation including fuel cell drones and autonomous vehicles.

Charlie Park, CEO of Doosan Infracore Europe, said: “The construction, quarrying and mining industries are becoming increasingly digitalised. We want to stay ahead by investing heavily in new technology for our product development, which includes investing in our drone solutions and automated machine control. We are also partnered with many big solution providers such as Trimble, Leica, Moba (Novatron) and now Palantir. We want to be known as the most technology-friendly brand in our markets.”

Looking to the Future with 5G

In what was one of the highlights of the Bauma 2019 exhibition in Munich in Germany, Doosan was the first manufacturer to use 5G technology for worldwide ‘TeleOperation’ of construction machines. Doosan has coined the term TeleOperation to describe the operation of construction equipment from a remote station. At Bauma, remote really meant remote – operating a Doosan DX380LC-5 40 tonne crawler excavator located over 8500 km away in Incheon in South Korea from an operator’s booth on Doosan’s Bauma stand.

New Fuel Cell Drones

Another eye-catching feature of Doosan’s stand at Bauma was a video demonstration of Doosan Mobility Innovation’s drones for monitoring and analysing machine performance and wider operation efficiency on construction, mine and quarry sites.

Later this year, Doosan is looking to demonstrate ConceptX, its wide-ranging digital technology development for construction and quarrying machines. Charlie Park added: “It will be an event in South Korea and we are aiming to stage it in November. It will show to customers, dealers and the market in general where Doosan is going on its product development. It will include our complete suite of solutions: control centres, cloud-based systems, digitalised machines, autonomous driving and our drones.”

Working More Efficiently

The new pre-installed Leica, Trimble and Xsite Ready Kits can now be ordered direct from the factory through Doosan Smart Solutions for use with Leica, Trimble and Xsite 2D and 3D machine guidance systems. Doosan also offers factory-installed SVAB/Steelwrist options for the company’s DX140W-5, DX160W-5, DX165W-5 and DX170W-5 wheeled excavators.

DoosanCARE Service Philosophy

As well as the standard functionality offered by the DoosanCONNECT system, the mobile app offers new functions such as directions to machines; call service, whereby the app connects the customer directly with the Doosan dealer’s service operation and a Chat option to send messages to the service provider.

DoosanCARE is a unique and direct customer care programme that offers ‘Total Solutions’ that are essential to customers’ business development, leading to long-lasting partnership and shared growth. Among the benefits provided by this proactive customer solution is a focus on improving machine productivity, increasing machine lifetime and planning service support on the customer side.

Charlie Park continued: “Our growth strategy is focused on having a more diverse product and aftermarket services offer. We want to differentiate from others with our higher level of product support and services. To do that, we are creating additional product offerings and improving our servicing capability, through DoosanCARE, and our replacement parts availability. Additional products will include new special application machines, like demolition excavators and material handlers, and increased attachment options, such as the tiltrotators.”