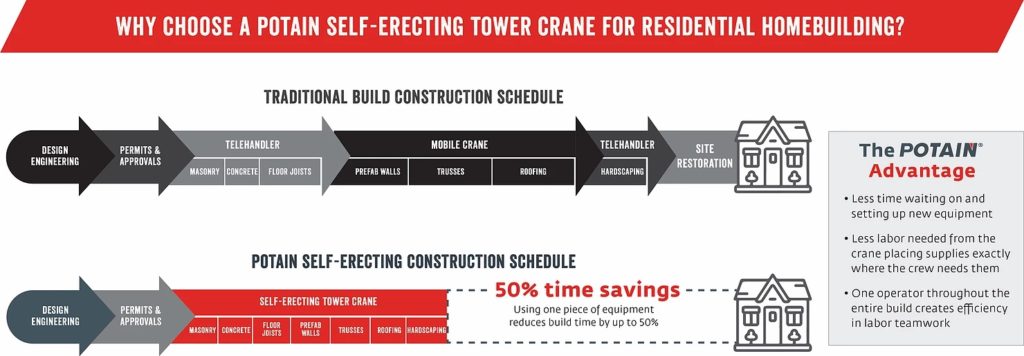

Potain self-erecting cranes are helping homebuilders overcome tight build timelines and restricted jobsites by building better, smarter, faster and quieter — all while reducing costs. Contractors across the U.S. report building homes up to 50% faster with these cranes when compared to conventional equipment such as telehandlers and mobile cranes.

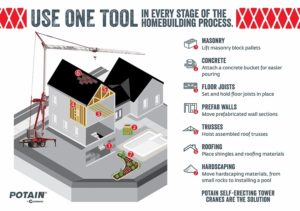

Potain self-erecting tower cranes are a mainstay of the global construction industry and are steadily strengthening their growing reputation in the residential homebuilding market throughout North America. These versatile cranes perform the jobs of several machines, reducing labor needs and dramatically increasing productivity on the jobsite. Contractors report building homes up to 50% faster with these cranes when compared to conventional equipment such as forklifts and mobile cranes.

From a small cross-base footprint, self-erectors boast ample capacity and extensive reach to access the entire jobsite. The quick erection time and ease of operation allow operators to perform lifts and place prefabricated materials — such as floor joists, wall sections and roof trusses — directly where they are needed. The radio remote control operation allows operators to be on the ground and navigate the work area, increasing their visibility and communication with other crew members, resulting in a more cohesive and productive team.

The impact of self-erectors in home construction can transform how companies approach projects. A great example is Pinetop Custom Homes (Pinetop), a homebuilder in McCall, Idaho. The company started with a single Potain Igo unit back in 2004, using it in place of a knuckleboom crane to assemble prefabricated developments. Today, Pinetop’s sister company, Rocky Mountain Crane, also based in McCall, operates a fleet of 25 Potain self-erecting cranes, covering both the Igo and Hup ranges.

From its very first experience using a self-erecting crane, Pinetop was quickly convinced with how the crane helped the crew build more cost-effectively. The company has steadily added more units to its fleet and uses the cranes to build homes from the bottom up, including various material handling lifts that help the crew build more efficiently. In effect, the company is building entire homes with Potain self-erecting cranes.

“We are able to build houses 50% faster with the self-erecting tower cranes than with other types of equipment,” said Dusty Bitton, owner of Pinetop. “They’re also easier to get to the jobsite. They have axles underneath, so you can just pull them onto the site. They’re silent from electrical operation and don’t produce exhaust fumes, and with their remote control, they really increase visibility and precision picking.”

“We are able to build houses 50% faster with the self-erecting tower cranes than with other types of equipment,” said Dusty Bitton, owner of Pinetop. “They’re also easier to get to the jobsite. They have axles underneath, so you can just pull them onto the site. They’re silent from electrical operation and don’t produce exhaust fumes, and with their remote control, they really increase visibility and precision picking.”

Savings in manpower

Bitton highlighted several other benefits Potain self-erecting cranes have over traditional machines, like forklifts and mobile cranes. For example, with a self-erecting crane just one machine can make lifts across the entire jobsite from a single location without being moved. Also, there are gains in manpower, as the same person can both operate and rig the load, which also improves productivity. And because the operator can move a load right in front of where they are standing, visibility and accuracy are improved, too.

Pinetop is currently employing Potain self-erecting cranes in two home projects in Idaho — one in McCall and another in nearby Stanley. At the McCall home build, the self-erector has given the crew access to areas where other equipment wouldn’t  be able to reach, which has greatly benefited workers and shortened the project’s timeline.

be able to reach, which has greatly benefited workers and shortened the project’s timeline.

“The crane has given the crew access to hard-to-reach areas that the topography wouldn’t lend kindly to other equipment,” Bitton said. “The crane has placed timber frames, roofing materials, rafters, tongue and groove ceiling panels, saving us approximately two months of construction time.”

At the second project in Stanley, in the Sawtooth mountains of central Idaho, Pinetop selected a Potain Hup 40-30 self-erecting crane for the remote location build. The crane selection ended up being the perfect choice to build a home on top of a ridge under a tight deadline before snow starts to fall in early autumn. Due to land limitations, there is no access for any other equipment on the south side of the structure, so the crew is using the self-erector to offload materials, frame the home and reach the side of the home that isn’t accessible any other way.

“This home couldn’t be built in this location within the short timeframe we have without the use of the Hup 40-30,” Bitton said. “The word is starting to spread about how much better it is to build with self-erectors, and how much time and money they can save.”