Steve Nendick, Marketing Communications Director at Cummins, looks at the future of power solutions for construction.

The off-highway sector is experiencing significant change. New global legislation and shifting end-user demands have prompted manufacturers to diversify their product portfolios to offer flexible, reliable and efficient power solutions with reduced emissions. Cummins, which celebrates its centenary in this year, is synonymous with diesel power, but we’re embracing this market shift by developing full-electric power and hybrid technologies.

Zero emission solutions

Ultra-low emission zones in urban centres have become an accepted standard for the on-highway sector. For off-highway, the equipment used in the construction industry is impacted, but to a lesser extent and the lowest emissions are being driven by tender requirements. Changes are happening and happening fast, as shown by the latest UK Clean Air Strategy and powertrain manufacturers have been collaborating with OEMs and legislators to ensure the industry is ready with a broad range of options.

In 2018, Cummins announced its plan to repower a standard diesel powered mini-excavator, removing the diesel engine and integrating a fully electric driveline. The result has been the creation of a 3.5-ton working prototype, powered by Cummins BM4.4E flexible battery modules (4.4 kWh each) mounted in the base of the excavator. These Cummins-designed Battery Modules utilise Lithium-ion technology and are able to operate for a full work shift, with a recharge time of under three hours.

The mini-excavator produces zero-emissions whilst operating with significantly reduced noise, making it an ideal solution for light duty cycles in densely populated urban centres. However, there are still limitations to what current generation full-electric power solutions can offer the manufacturers and operators of heavy plant and equipment.

Goodbye diesel power?

For many OEMs within construction the industry, electric technology cannot yet produce the necessary power solutions for heavy duty usage. These requirements are more often than not still met with diesel power.

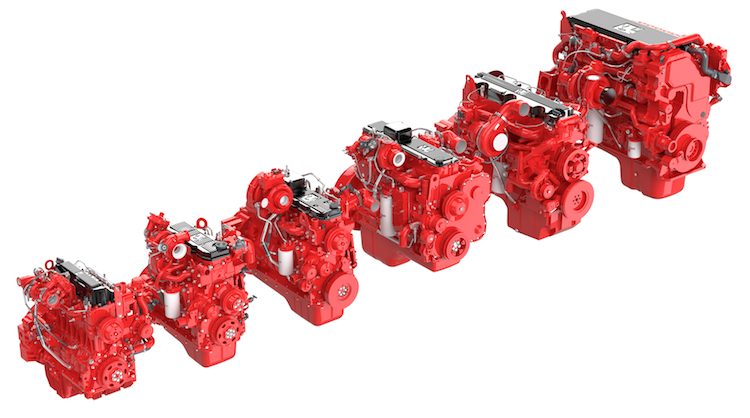

It can definitively be said that “diesel” has become a negative term in the public conscious over the last decade, however with Stage V emissions legislation, the technology involved in diesel combustion has never been cleaner. The latest generation of Cummins engines are smaller, lighter and simpler than ever before, emitting ultra-low NOx and PM emissions due to innovative aftertreatment technology. The ultra-low emission development of these units has not compromised the power density available either, with an average of 10 per cent more power and 20 per cent more torque available across the 100 hp – 430 hp range, compared with previous Stage IV counterparts.

Finding the best solutions

The reality of near-future power solutions is likely to be a combination of electrification, hybridisation and ultra-low emissions diesel technology. Cummins is committed to developing solutions for all off-highway requirements and has been investing heavily in R&D to ensure it can deliver this effectively, as shown by the development of the fully electric mini excavator, the Stage V engine range and the integration of our Hybrid Power Plug-in (HPP) system.

Cummins’ HPP driveline combines battery power with an ultra-clean diesel engine, and can be scaled to fit a variety of equipment types. The current F3.8 engine and BPcE battery combination uses a high efficiency traction motor to provide a continuous torque of 1,850 Nm, with an instant peak torque boost of 3,400 Nm available in difficult working conditions. The HPP eliminates the need for traditional gear shifting, creating more space for OEM designers and reducing operational noise levels.

Off-highway vehicles fitted with hybrid systems such as the HPP driveline can operate in the space between light duty cycle use, suited to fully electric power solutions, and heavy duty applications that still require the brute power and endurance of diesel power.

Key to embracing changes across the industry will be the ability for OEMs to collaborate with manufacturers to find the appropriate power solutions and meet market demand. The great diversity of plant machinery design and working conditions means that their power solutions are not one-size-fits-all. As progression in electrification is made then its suitability for industrial machines will increase. However, the advances in ultra-clean diesel technology demonstrate that it will continue to be the go-power source for plant machinery for the foreseeable future.

100 not out…

Cummins is celebrating its 100th year in 2019, a celebration of heritage in a constantly evolving industry, during a very changeable time. Whilst looking back at past achievements, there is a great focus at Cummins on delivering a diverse range of future power solutions to an expanding market. The industry is shifting on a truly global scale and Cummins is ready to deliver innovative low to zero emissions power solutions in day-to-day applications.