A new, real-time telematics platform for the construction industry is being trialled. CPN hears from the two companies behind the science.

Managing machine hours, tracking fuel usage, and monitoring load capacities are set to become simpler and quicker thanks to PVS Data. The company’s new D2 unit allows access to over 300 real-time data parameters, including live engine reports, precise machine locations through the w3w (What 3 Words) app integration, and safety metrics, including height, slew, and RCI (rated capacity indicator) data from Xwatch Safety Solutions.

According to Dan Leaney, Xwatch’s sales director, “the telematics system for the D2 units from PVS, branded as XW-Insite by Xwatch, represents our most advanced safety. and telematics solution to date. Currently being trialled with a leading plant hire firm, a tier-one contractor, and through PVS’s own trials, this system integrates Xwatch’s precise height, slew, and RCI data with PVS Data’s cloud-based platform. It delivers seamless telematics access across fleets, covering all major equipment brands.

“Operators can configure and monitor critical safety parameters directly from the cab, while managers gain real-time visibility into machine performance and safety metrics, whether on-site or working remotely. This innovation is designed to prevent accidents, reduce downtime, and enable smarter, data-driven decisions. At Xwatch, we are proud to collaborate with PVS to lead the industry in making construction sites safer and more efficient, and we look forward to seeing comparable data emerge from these trials in the coming months,” he added.

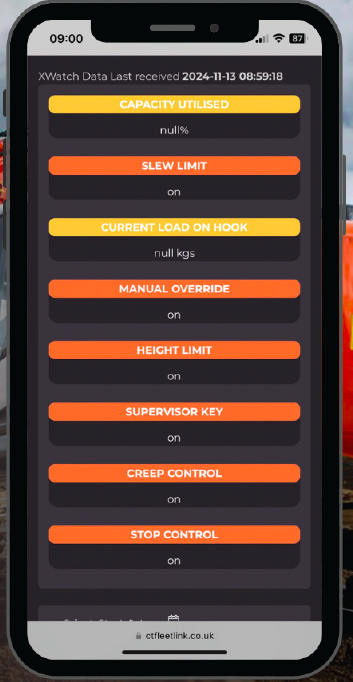

This collaboration between PVS Data and Xwatch Safety Solutions is claimed to bring powerful functionality to fleet management and provide seamless access to telematics across an entire fleet, covering all major brands, including JCB, Sany, Hitachi and Takeuchi to name a few. Site managers gain a clear visual overview of their machinery equipped with Xwatch Safety Solutions. They can monitor height and slew settings, view the exact weight on the hook, confirm whether stop and creep controls are active, and analyse overall capacity utilisation — all in real-time.

Combine this safety information with realtime data such as fuel usage, engine performance, fault reporting, idle and productive hours, and carbon dioxide emissions and the result is a construction site that operates more efficiently, ensures greater safety for ground personnel, meets zero-emissions goals, reduces costs and downtime, extends machinery life, and encourages smarter machine operation.

Scott McCabe, owner and director of PVS Data, commented: “Heightened safety on site has been at the heart of the industry for decades. Our partnerships with innovators like Xwatch make the platform the logical all-in-one solution for fleet health and safety. We’re excited to see where our current trials take us, advancing the platform to show a greater number of meaningful data parameters, and growing our partnership with the Xwatch team”.