Information gathered in a worldwide project to report accidents and near-misses has informed a major update to a comprehensive training course on how to load and unload MEWPs and other plant equipment safely from trucks or trailers.

The latest analysis of global data gathered by the International Powered Access Federation (IPAF) shows most accidents, resulting in lost-time injuries and even on occasion fatalities, during delivery of MEWPs occur during loading or unloading. As a result, IPAF decided to overhaul its existing Load/Unload course, with new training materials being unveiled to instructors in a Professional Development Seminar on 11 November.

Peter Douglas, IPAF CEO & MD, comments: “Last year IPAF invested time and resources into updating its ongoing worldwide accident reporting and analysis project, leading to a new comprehensive industry-facing Global MEWP Safety Report. Earlier this year we updated and relaunched our Incident Reporting Portal, aimed at gathering even more granular data about not just accidents but also near-misses.

Peter Douglas, IPAF CEO & MD, comments: “Last year IPAF invested time and resources into updating its ongoing worldwide accident reporting and analysis project, leading to a new comprehensive industry-facing Global MEWP Safety Report. Earlier this year we updated and relaunched our Incident Reporting Portal, aimed at gathering even more granular data about not just accidents but also near-misses.

“Satistically the most likely people to be involved in a MEWP-related incident are those loading and unloading and these operatives are key to our industry. Analysing data has allowed the updated training course to directly address those issues that affect people loading or unloading, and provide knowledge and recommended protocols to help prevent accidents before they happen.

“This is exactly the reason why we place so much emphasis on our accident reporting project – only through good data and exhaustive analysis of accidents and near-misses can we identify high-risk situations, uncover underlying causes of why operators get into difficulty, and address these through our training programme, industry technical guidance, Andy Access safety campaigns and Toolbox Talks series.”

Paul Roddis, IPAF Training Manager, says: “The IPAF Load/Unload course has been reviewed off the back of the accident statistics showing that the people most likely to be harmed in a MEWP-related incident are delivery drivers. We believed that there was more the course could offer in terms of equipping and protecting operatives loading and unloading MEWPs, and we wanted to do more to help protect them. This updated training course does exactly that.

“We set up a working group formed of members of the IPAF Training Committee, led by Martin Wraith, an IPAF auditor and qualified training instructor, as he also has significant experience within the haulage industry.

“The revamped training is still an instructor-led theory course, though it has a completely new look and feel. We were able to incorporate information directly from the incident-reporting portal, to fine-tune the training so that it addresses the most common problems and risk scenarios anyone loading or unloading machines might face.

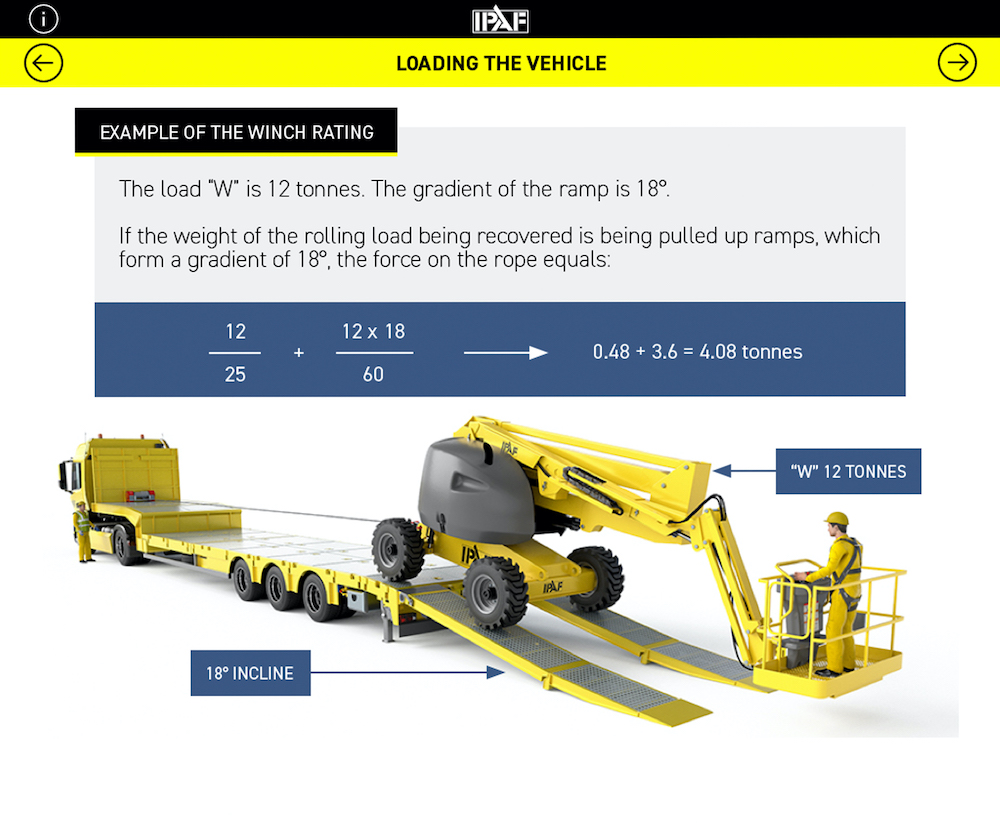

“In terms of visual enhancements, the new course incorporates a new IPAF fleet of delivery vehicles starting with a 4×4 with trailer, a 3.5t flat-bed van, a 7.5t beaver-tail, as well as a 26t rigid and a 40t articulated HGV trailer.”

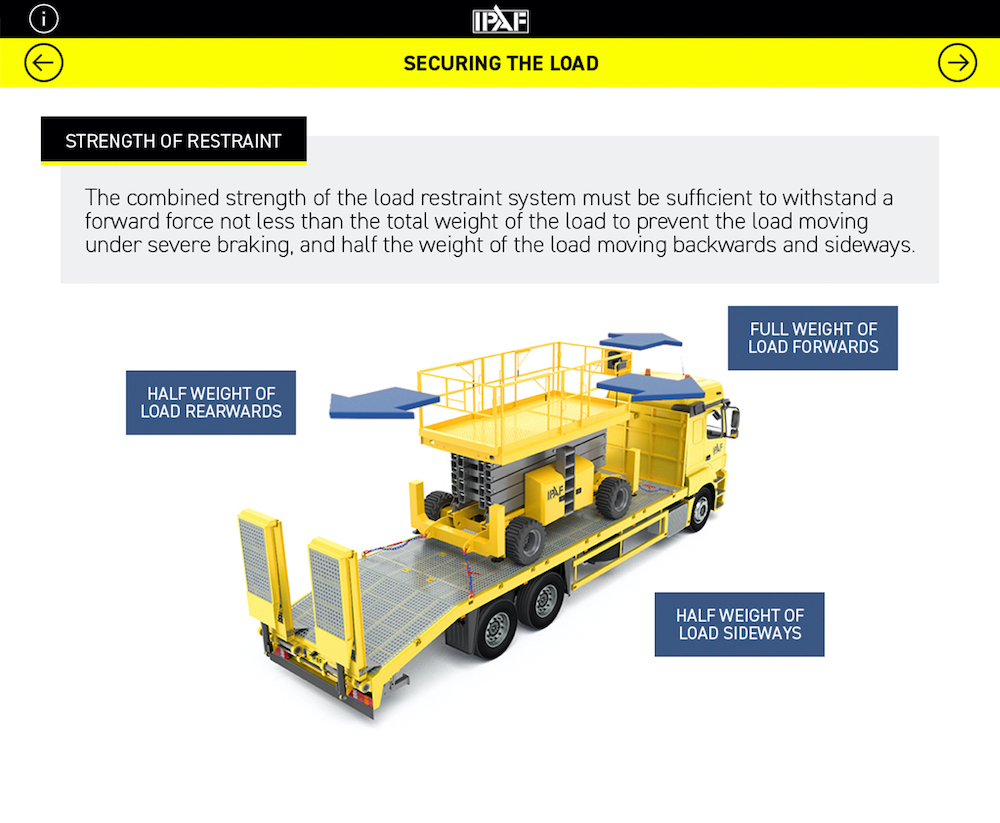

All information covered in the course content conforms to EN 12195 Load-restraining on road vehicles — Safety and references both the IPAF best practice guidance Load and Unload and Loading And Unloading Mewps on the Public Highway.

Roddis adds: “This is an excellent new course to complement those that IPAF Training Centres already offer. It is highly recommended learning for anyone operating, hiring, maintaining, delivering or managing MEWPs; there is a great deal in the training course that is applicable to a range of plant machines, including dumpers, diggers, telehandlers, rollers or forklifts.

“I’d like to thank Martin Wraith and all those who sat on the working group, along with the IPAF UK Country Council, Training Committee and our brilliant network of Training Centre staff and instructors, who I know will roll the new version of this valuable course out with enthusiasm and vigour, to assist candidates taking the course to understand and identify the common risks involved, and to protect themselves from harm while loading and unloading powered access equipment.”