With passport in hand he’s off. Some say he approaches machine testing in a zenlike state, others that his enthusiasm is boundless. All we know is that we call him The Dig. This month he goes a few rounds with Bobcat’s updated R2 range.

Bobcat has completely revised its successful line up of mini excavators in the one to two tonne class and in doing so completed the R2 range.

In October last year we were invited along to an exclusive test drive opportunity ahead of the machines’ first public appearance at Bauma 2025 last month. In an interesting event, undertaken in almost complete secrecy within the confines of a walled garden somewhere in the Czech Republic countryside, we had the privilege to be able to spend an entire day with the new machines, with nothing being too much bother for the assembled team from Bobcat. From my point of view, this is just what I want from a construction machinery reveal, time to spend around the kit, and indeed getting that “hands on” feel for the new models.

Upgrades all round

Upgrades all round

Bobcat first launched its updated R2 range of mini excavators back in 2021 and has been gradually updating the entire range since then, the four one- to two-tonne models are the final pieces in the R2 range jigsaw. The 1-2-tonne mini excavator is an important sector in the European market. The four previous Bobcat models in this size class have proven to be best sellers in the EMEA region with a total of well over 34,000 units having been sold, most of which have been manufactured at the company’s state-of-the-art factory in Dobris, Czech Republic.

The long-awaited upgrade is now complete and the four new R2 models took centre stage during Bauma; the models are E16 (1,612 kg), E17z (1,712 kg), E19 (1,905 kg) and E20z (1,980 kg). Replacing the previous entry-level model E17, the E16 R2 is 100kg lighter than its predecessor. The models marked with a ‘Z’ are as Bobcat describes it, ‘Zero House Swing’, or ZHS versions, in which neither the rear nor the front corners of the upper carriage protrude beyond the track when slewing the machine.

The E16 and the E19 both feature a conventional rear tailswing. The option of having the choice of conventional swing or zero tails swing in the similar weight class, is driven by different demands from European markets. It was explained that this is largely due to countries having different legal requirements for towing machinery on a trailer, but also the fact that zero tailswing machines suit small builders who are often working in confined spaces.

New components

Bobcat states that the new machines have over 500 new components on them, many of which you probably wouldn’t notice until they are pointed out to you. I was given a walkaround tour of the new machines by Miroslav Konas who is the product manager for Bobcat excavators, and he pointed out the major differences.

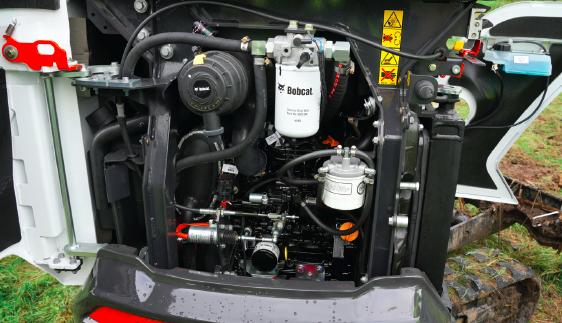

The initial standout design change, and most notable when the M and R2 Series machines are parked side by side, is with the offside rear radiator grill panel, much larger than on the previous model, this panel is made of tough impact resistant plastic. It opens outwards to allow great access to the major components, and with the rear panel door open, it provides superb access to the engine bay, which is host to the very latest

Stage V emission compliant, Yanmar 3TNV74 3-cylinder 11.0kW diesel engine. Little touches have been added which might not initially get noticed, for instance, larger tie down points on the upper structure for improved strapping down during transport; there is also the addition of metal protective framework around the roof mounted LED work lights. A new under boom LED work light is also fitted, nicely protected from any potential damage. I also noticed the so-called ‘3D’ door entry handle that we have seen rolled out on previous R2 Series machines. And while talking about the cab exterior, I noted that the cab door locking mechanism has been moved out of the glazed area and relocated to the cab framework, which can be beneficial if the glass gets smashed.

Talking of glass, on the E20z short-tail model the door mount pillar has been moved back slightly, this means when the door is in its locked open position it does protrude out a bit beyond the main body, which could make it slightly vulnerable to damage, but that is the compromise in going for a zero-tail swing model.

As a result of customer feedback on the previous models, the gap between the top of the track and the upper carriage has been increased, a common complaint previously was that work boots could get trapped in the gap, this issue has now been addressed.

The floating dozer blade has been redesigned for strength and angled forward to prompt easy rolling over of the material being pushed. In common with other Bobcat mini excavators the offset boom ram is safely situated on the left-hand side of the machine, in full view of the operator, instead of on the offside where they can sometimes be exposed to accidental damage often unseen by an operator.

At the business end of the dipper arm a new and improved bucket link mechanism has been fitted. In addition, up to five additional hydraulic circuits are now available for running hydraulic attachments, and of course factory fitted piping for the hydraulic quick coupler. These lines on the E19 and E20z are now extended right up to the stick.

On board

Climbing up into the cabin and I instantly get that feeling of familiarity of the Bobcat R2 series, the combination of stylish black and grey plastic trim gives the machine a quality feel. A clean-cut removable rubber floor mat is provided and there are no other foot pedals to clutter up the space, other than the sturdy looking fold away tracking pedals, which as we have seen on previous R2 models, have neat little rubber pads to prevent any annoying rattles when they are folded up. Sometimes it’s the little simple things that can make a big difference to an operator’s life.

The seat, which I assume was made by Grammar, was incredibly comfortable, with what I found to be exceptional support around the back and the lumber position, there are minimal buttons in the cab which keeps things nice and simple and most of them fall nicely to hand. This is with the exception of the heater controls, they are mounted down on the lower right-hand side of the cab, so you have to reach down to adjust the heat/cool air flow, but it’s no big deal in the wider scheme of things.

Talking of air flow, for those who love the fresh air, both offside windows slide open to allow for a free flow throughout the cabin area when needed. Various measures have made it possible to reduce the noise level inside the cabin by up to four dB(A), depending on the model, which is impressive, as is the general allround visibility, as there is a lot of glass in this ROPS specified cabin.

The joysticks have a high-quality feel and they are fitted with proportional rocker switches for running the additional hydraulic circuits and for the off-set boom function, which although I have always preferred a right-hand side foot pedal for that function personally, this did feel very intuitive after 10 minutes on the machine.

The new full colour display to the righthand side of the operator provides all the usual machine status feedback such as oil and water temperatures, fuel level, hours worked, and is used to make numerous other settings, such as AUX hydraulic flows for different work tools, which can all be adjusted via the screen menu.

The dozer control lever is located in the industry standard position and in the same way, a two-speed tracking button is conveniently located on the top of the lever. A simple push-pull lever is provided to control the throttle speed and I really like that simplicity, the only thing that confuses me is having to push the lever forward to increase the engine power, traditionally you tend to pull back on the lever for full power, but it’s reversed on these machines, however you soon learn to cope with it after a bit of mind training!

The new load-sensing hydraulic system is a real highlight on the R2 series machines and according to product manager Miroslav Konas, promises significant advantages in terms of performance and fine controllability. The change in the functionality and the superior performance of the new hydraulic system were well demonstrated by Bobcat bringing along an older E19 machine for us to do a comparison between the old and new machines.

The difference in performance was quite noticeable; on the old model it was hard to use multiple movements without one dragging the other down, in addition straight tracking could be an issue; however, none of this occurs with the new hydraulic system. It was even possible to operate an additional circuit while working movements are being carried out at the same time.

A prime example of this was when I was invited to run a flail mower under the E20z. I quickly found I was able to use the mower, track and slew at the same time, with virtually no loss in power in either function, which was pretty impressive to be honest!

Great feedback

Both myself and German media friend Dirk Bömer, who also comes from a long-standing machine operator background, were very impressed with the machine’s super smooth hydraulic functionality, especially when grading material which is always the big test for machines in general. As Dirk suggested, when grading material at least three movements are generally carried out simultaneously, we were both in our element as we went about our business in the field enjoying the time on the new Bobcats!

Feedback through the levers is really good and effortless. It was an absolute joy to use in a grading application, in fact it didn’t really matter what you were doing with the machine, it felt very refined and positive in every aspect.

The deployment of larger hydraulic cylinders enables the machines to offer greater digging forces and more powerful lifting. I put the E19 R2 to the test lifting a heavy weight which had been set up for us; it coped admirably, and although you knew you had the weight on, it was never a problem, whereas the previous E19 model struggled to move it off the ground.

Mini excavators are used for so much more these days, with a vast range of attachments available they are increasingly utilised as tool carriers. These new 1-2 tonne models with cutting edge hydraulics are sure to appeal to the Bobcat faithful and new customers alike, and it’s not hard to see why, from my experience with them on the day, I would be more than happy to spend my time in the seat of one.

More information on Bobcat mini excavators