With Spring in the air, it’s time for action. Some say he operates a machine like a chess grand master , others that he has the deftness of a concert pianist. All we know is that we call him The Dig. This month he gets to play with JCB’s 145XR.

Zero tail or reduced radius hydraulic excavators are becoming ever more popular on urban jobsites, especially in the house groundworks sector, with sites getting ever more cramped as developers try to squeeze in as many plots as possible. So JCB’s 145XR will fit in nicely, literally.

The long-awaited machine is the second reduced tailswing machine in the X-Series line up, joining its larger brother the 245XR which was launched back in late 2021. Of course, those of us in the UK had already seen the machine in public when it took centre stage on the JCB stand at Hillhead last year. However, this was a first opportunity to get up close and personal with the new model, and to spend some time on the levers.

Following an evening reveal of the 145XR, all theatre and razzamatazz, I trooped down to JCB’s own Kevin Quarry facility the next morning. It was in this setting that the star of the show got to strut its stuff. Typically, the local weather did its best to put a damper on the proceedings as a heavy mist filled the quarry, but it was a case of lights on and crack on with the show!

Close encounters

Keen to find out what makes this new machine tick, I took a closer look around. Climbing up to the engine bay is reassuringly easy, thanks to three decent sized anti-slip steps, with sturdy looking hi-viz green hand rails guiding the assent.

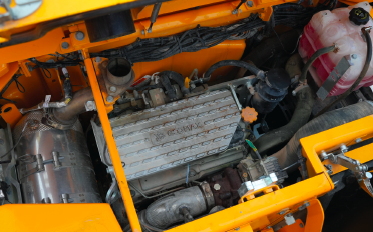

Popping the bonnet latches, and it was no real surprise to discover that the 145XR features the familiar and well proven Stage V emissions compliant JCB Dieselmax engine, which is the same power pack fitted in the conventional tailswing 140X model, and offers a power output rating of 81kW (108hp).

Following the format for reduced tailswing machines, curved rear panel doors open outwards for access. On the nearside rear it’s home to the cooling packs, air filter housing, batteries and washer bottle. Wandering around to the offside and I discover the heart of the machines hydraulic system, with the latest Kawasaki hydraulic pump.

Also located in this area are the fluid filters, all nicely grouped to be easily accessible for regular servicing from the ground level. I love how this has become the industry standard layout now, compared to the days when I was changing filters mounted on the side of an all too often scorching hot engine block. Thankfully, it’s so much easier and safer now. Talking of filters, the hydraulic oil filter change interval has now been increased to 2,000 hours.

Also accessible from ground level is the AdBlue tank, which, on this model, is located towards the offside front behind a lockable panel door. This space effectively below the steps, is also home to the electric refuelling pump and pipework, essentially a one stop shop area for topping up, without the need to be climbing up on top of the machine.

Walking around the rear counterweight area gives a real sense of the machine’s compact features. According to JCB the 145XR is 27% shorter in tailswing than the conventional 140X model and combined with its reduced front swing capability, it’s an impressively compact package.

No compromise

So often with zero or reduced radius machines, there is a compromise in that the cab space is significantly reduced, something I have heard from operators on numerous occasions and experienced myself as an operator.

However, JCB breaks the rule book on that front, as the fitted Command Plus ROPS cab is 100% full sized, in fact this cab is the same size right across the X-Series range of hydraulic excavators, boasting a whopping 2.86m3 of interior volume.

I have waxed lyrical about the X-Series cabs in a number of previous reviews, and as far as I can see my opinion still stands proud, it really is one of the best cabs on the market, superbly finished in an automotive style, well-appointed and every feature is right where an operator would want it to be, with its heated air suspension seat. Safe to say, it’s a pure delight to spend a shift in them, as it has totally been designed with the operator in mind.

In addition, as we saw in the recently launched 370X, the cab is further enhanced with the addition of the new 10in touchscreen monitor with the JCB UX interface. The monitor features amazingly clear graphics and a raft of functions can be accessed using the touch screen.

If it’s their thing to tinker about with functions, the operator can personalise it to his or her own requirements and adjust up to 15 hydraulic attachment flow settings via customisable hot keys. Up to 25 user profiles can be stored on the system, allowing individual operators to fine tune such things as joystick configuration to their preferred set up.

Climate control, and mobile phone connectivity is also featured on the monitor, which is also home to twin camera screens for rear and/or offside views. A 360° birds eye view camera option is also available if required. Incredibly for those who are not tech savvy, there are also ‘how to’ videos available in the system, which cover all the features of the UX monitor system.

Quick, lively, accurate

Quick, lively, accurate

As always, I didn’t need a second invitation to get aboard the machine. I do love spending time on an excavator and it’s always great to get back in the seat as often as possible. Having settled into the seat and secured my seatbelt, I went through the motions to get the machine started. Being a keyless affair, I turned the rotary dial on my right hand-side, punched in the code on the screen and pushed the start button, after which I was greeted with the gentle thrum of the 4-pot JCB power pack.

The test drive followed a familiar script here in the JCB quarry, with a pile of limestone in front of me which I could play with to get a feel for the machine. A quick tug on the lever and the machine switched from auto-idle to full power. From the quarry floor, I made a slight ramp up on to the heap, the machine was in hare mode for tracking, and although it had geared down automatically, I decided to select tortoise mode for improved traction and to gain the full benefit of the machines 127.5kNm of tractive effort.

Once on top of the heap I proceeded to throw some material around to get that initial feel for the machine’s mannerisms when working under load. My first reaction was wow, this is quick, and it certainly proved to be lively on the stick and in the slew, tracking and using the boom and dipper seemed to present no problems either.

Once I had got used to its behaviour, I started to do some trimming work to get a feel for its gradeability, it didn’t disappoint in that department either. This machine featured the standard mono boom and UK industry standard 3m dipper, which gives the machine a maximum reach at ground level of 8,801mm and a maximum dig depth 6,027mm.

Weighty matters

The European favoured TAB (two-piece boom) option is available too which would be an outstanding set-up and even more so by adding the optional dozer blade too, but this one was the standard UK spec with a direct mount quick hitch.

The machine continued to impress me with its smooth and fast performance, but it did feel like it could do with a bit extra weight on the rear end, especially when reaching out with a full bucket over the side, which did unsettle the machine a bit, a little bit more weight and a slightly longer and wider undercarriage should do the trick.

Overwhelmingly though, this will be a great addition to the X-Series range, and with a few tweaks will prove to be very popular with groundworks contractors.

More on JCB’s 145 XR