The jury have made their decision: The 2022 Bauma Innovation Award in the climate protection category goes to the R 9XX H2 hydrogen excavator. This is the first Liebherr hydraulic excavator to be powered by a hydrogen engine.

Working on alternative drive solutions, Liebherr takes a technology-neutral approach. Hydrogen combustion engines are one technology being explored by the Group. The R 9XX H2, Liebherr’s first hydrogen-powered crawler excavator, has now won the Bauma Innovation Award. The prototype was developed by Liebherr-France SAS, based in Colmar, France. The machine is powered by an H966 hydrogen combustion engine. It was produced at Liebherr Machines Bulle SA, the Liebherr Group’s engine competence centre in the Swiss canton of Fribourg.

In terms of power, dynamics and responsiveness, the R 9XX H2 hydrogen excavator gives nothing away to any conventionally powered machine. Nor is it dependent on a continuous energy supply either. The emissions make the difference: On a “tank to wheel” basis, i.e. when used on a construction site, a hydrogen excavator emits almost no CO2. “Cradle to grave” or from production to decommissioning, CO2 emissions are 70% lower than those of comparable conventionally powered excavators. Suitable for use under extreme temperatures, shock, and high-dust conditions on construction sites, the 50 tonne-operating weight R 9XX H2 may in future offer a robust solution for earthworks and quarrying applications.

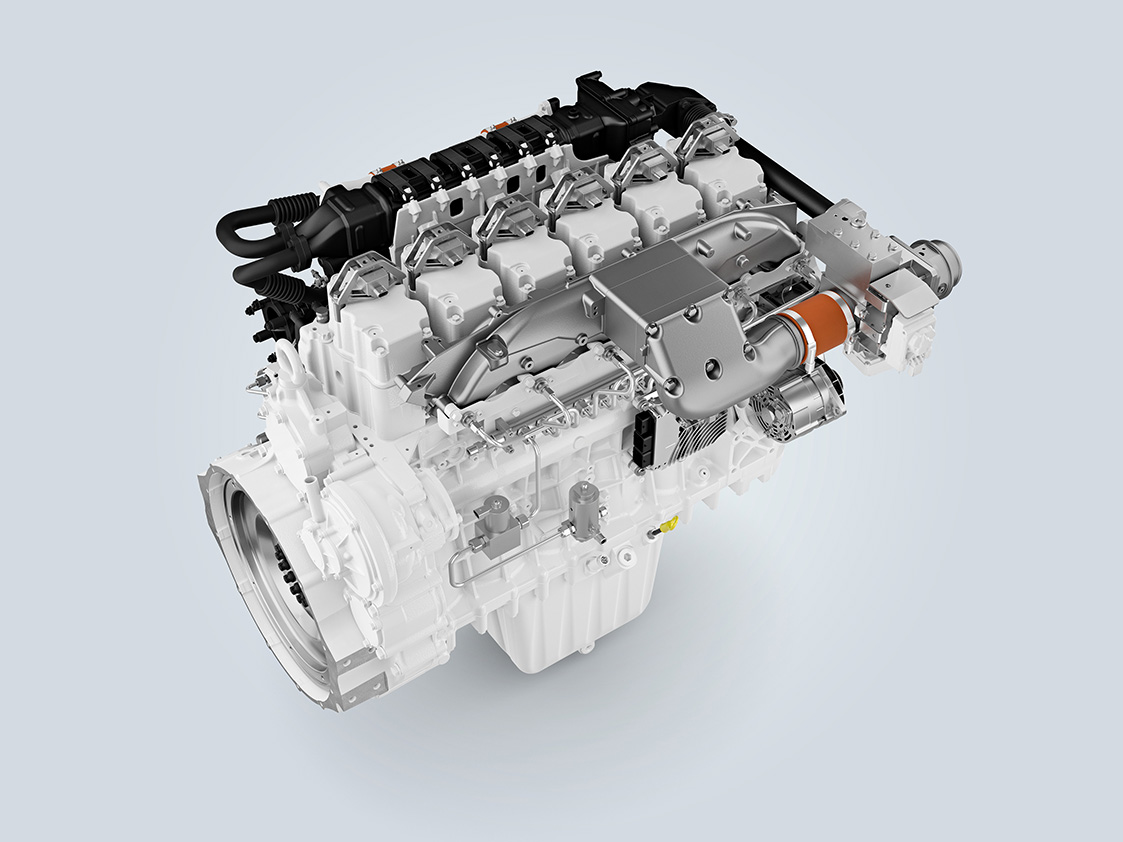

The R 9XX H2 is powered by a Liebherr H966 hydrogen combustion engine. The engine has six cylinders and uses port fuel injection (PFI), which Liebherr employs along with direct injection (DI) for its hydrogen engines. Liebherr’s components product segment plans to start with the series production of hydrogen motors by 2025.

Visitors to the Bauma fair in Munich can experience the Liebherr R9XX H2 hydrogen excavator live from 24 to 30 October 2022. The excavator is part of a machine show at the Liebherr booth in the outdoor area, where the company is exhibiting a variety of machines and prototypes with alternative drive systems. The booth even offers a hands-on encounter with the second prototype of the H966 hydrogen combustion engine. It can be found in the “InnovationLab”, an exhibition area devoted to Liebherr’s open approach to alternative drive concepts. Another four-cylinder prototype of a 4-cylinder hydrogen engine, the H964 with direct injection (DI), can be seen at the Liebherr Components booth 326 in hall A4.

The Bauma Innovation Award

2022 sees the thirteenth presentation of the Bauma Innovation Award. Its five categories – climate protection, digitalisation, mechanical engineering, building and research – reflect political, social, economic and ecological challenges. The expert jury’s focus on criteria such as practical orientation, economic potential, environmental protection aspects, resource conservation, efficiency and humanisation the workplace. The prize is awarded by Messe München and the German Mechanical Engineering Industry Association (VDMA), together with the Federation of the German Construction Industry (HDB), the German Construction Confederation (ZDB) and the German Building Materials Federation (bbs).