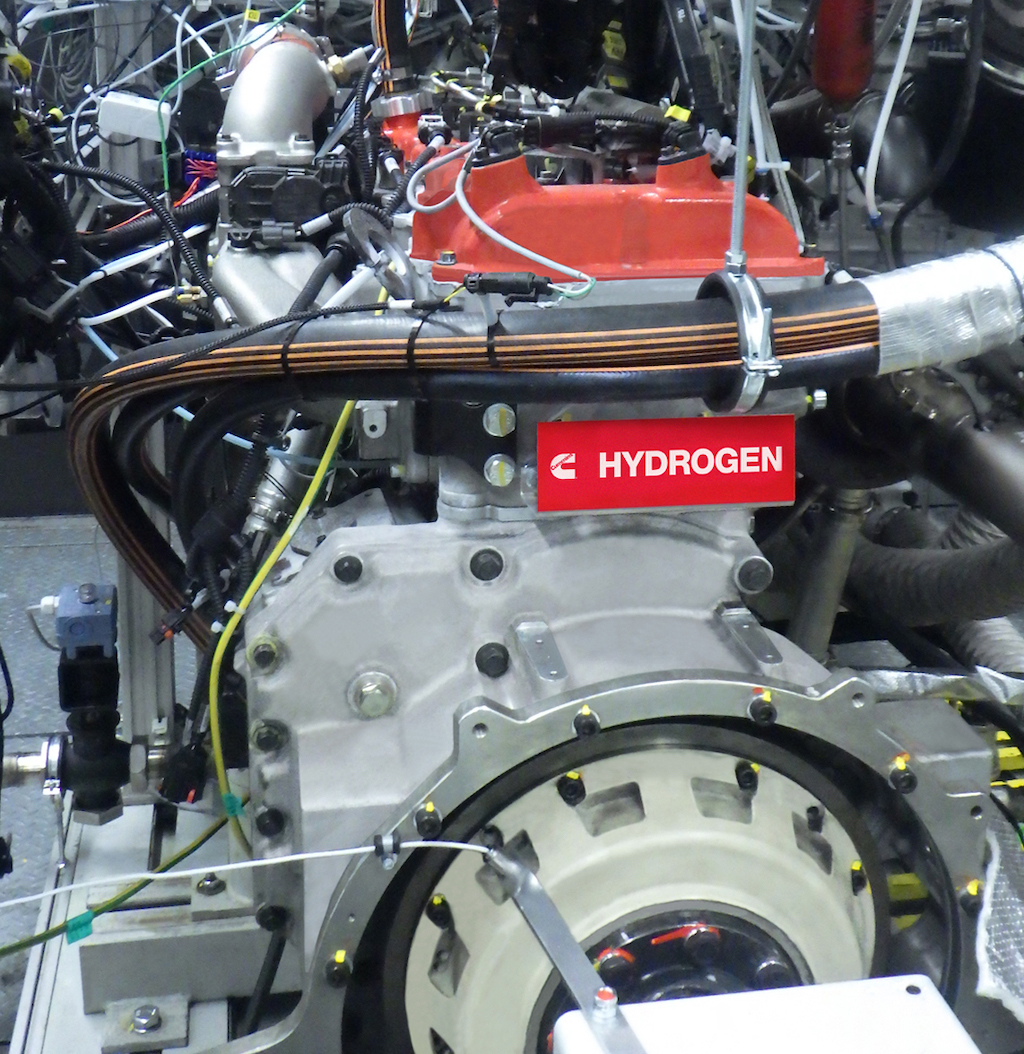

Cummins hydrogen-fuelled internal combustion engine (H2-ICE) programme is ready to move ahead with the development of a medium-duty 6.7-litre and a heavy-duty 15-litre engine.

Based on next generation platforms, the new hydrogen engines will aim to achieve zero carbon emissions, enhanced power density and improved thermal efficiency.

The engine development work will be accelerated after receiving a £7.2 million funding award from the UK Government provided through the Advanced Propulsion Centre (APC), recognising the potential for H2-ICE to play a major role in decarbonising commercial trucks and construction equipment from 2025 onward.

Designated as the APC18 BRUNEL Project, the technical readiness work will expand on Cummins’ experience from its existing H2-ICE programme and recent proof-of-concept testing. Planned development of the 6.7-litre hydrogen engine will focus on medium-duty truck, bus, and construction applications, such as excavators and wheel loaders. A new 15-litre platform offers the potential to bring hydrogen gas-fuelled engine capability to long-haul trucks with up to 44-ton gross vehicle weight and other heavy-duty applications.

The APC estimates that successful execution of the Cummins H2-ICE project could reduce more than 11 million tons of carbon emissions annually, equivalent to the emissions of 2.4 million cars in the UK.

UK Minister for Investment Lord Grimstone said: “The BRUNEL Project is carrying on Darlington’s long tradition of skilled engineering, which will continue to grow for many years to come. We are working to build back better and greener after the pandemic and government investment in this scheme will help secure a better future for the next generation.”

Cummins European Technical Centre at the Darlington facility will oversee a consortium of leading sub-system manufacturers in the UK to achieve commercial viability for H2-ICE.

The estimated £14.6 million cost of the H2-ICE technical readiness project will be funded by the APC award of £7.2 million and additional investment by Cummins and industry partners.

“Confirmation of the strategic support awarded by APC is excellent news for Cummins and our world-class research and development facility at Darlington UK as it will accelerate the pace of our hydrogen engine development,” said Antonio Leitao, Vice President, Cummins Europe Area Business Organisation.

A significant advantage of hydrogen-fuelled engines is their ability to reduce vehicle and equipment re-development timelines, as many existing driveline components can be retained.

“With a leading presence in the global natural gas vehicle market, we can leverage our extensive knowledge of gaseous-fuelled technology to meet our goal of delivering market-defining hydrogen engine platforms to help customers around the world decarbonise their fleets,” commented Jonathan Atkinson, Executive Director of Cummins On-highway Business in Europe.

Expanding the Hydrogen Ecosphere

Cummins partnership with hydrogen storage specialist NPROXX adds an important resource in terms of integrating the hydrogen engine, with the high-pressure gas tanks and supply lines installed on the vehicle or equipment.

The APC18 project will ensure that the Cummins facility at Darlington will be at the forefront of H2-ICE technology, complementing the company’s range of decarbonisation solutions alongside hydrogen fuel cell and battery electric powertrains. Cummins pivotal role in expanding the hydrogen economy also extends to the manufacture of renewable green hydrogen by proton exchange membrane (PEM) electrolysers, uniquely linking a Cummins hydrogen ecosphere from production to vehicle power and fuel storage.