Offering fuel efficiency improvements over conventional machines of 17%, Volvo has launched an all-new powertrain for its revolutionary EC300E Hybrid excavator – and introduced the technology in two new models in the 25 and 35-tonne classes.

Using an all-new base machine that itself offers a 10% improvement in fuel efficiency over the model it replaces, Volvo Construction Equipment (Volvo CE) has introduced three new hybrid excavators that offer a further fuel efficiency improvement of up to 17% compared to conventional machines. The new range comes in the form of an enhanced 30-ton class EC300E Hybrid excavator, and the introduction of the technology in two new machines – the 25-ton class EC250E Hybrid and 35-ton class EC350E Hybrid.

Harvesting Boom-Down Energy

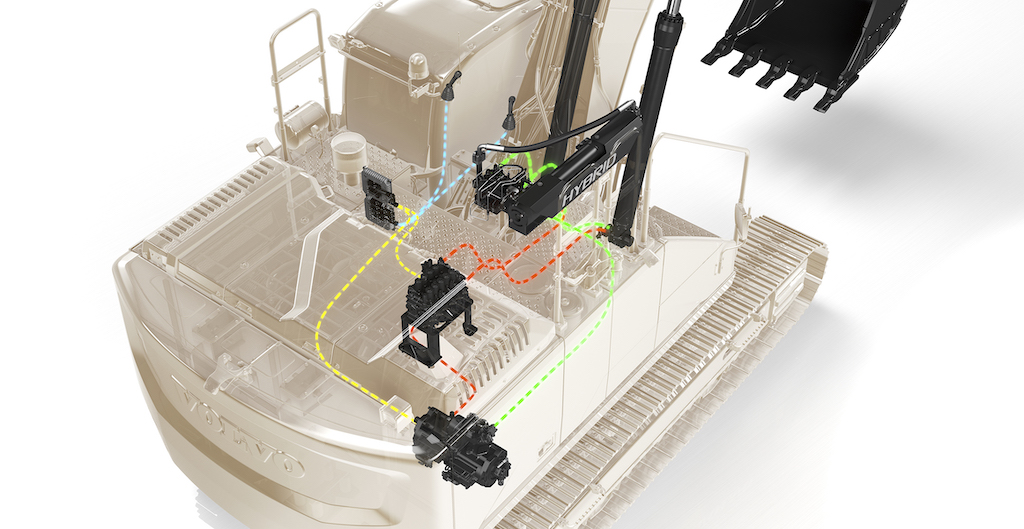

All three machines use Volvo’s novel hydraulic-hybrid technology that harvests ‘free’ energy generated by the down motion of the excavator’s boom. The powerful and regular boom-down motions charge a hydraulic accumulator, which then stores and delivers energy, when needed, to drive the hydraulic assist motor that helps power the engine system. The Hybrid models involve no compromise in ability, with these excavators offering the same levels of controllability and performance as the standard machines, including being able to work in ECO mode and Hybrid mode simultaneously.

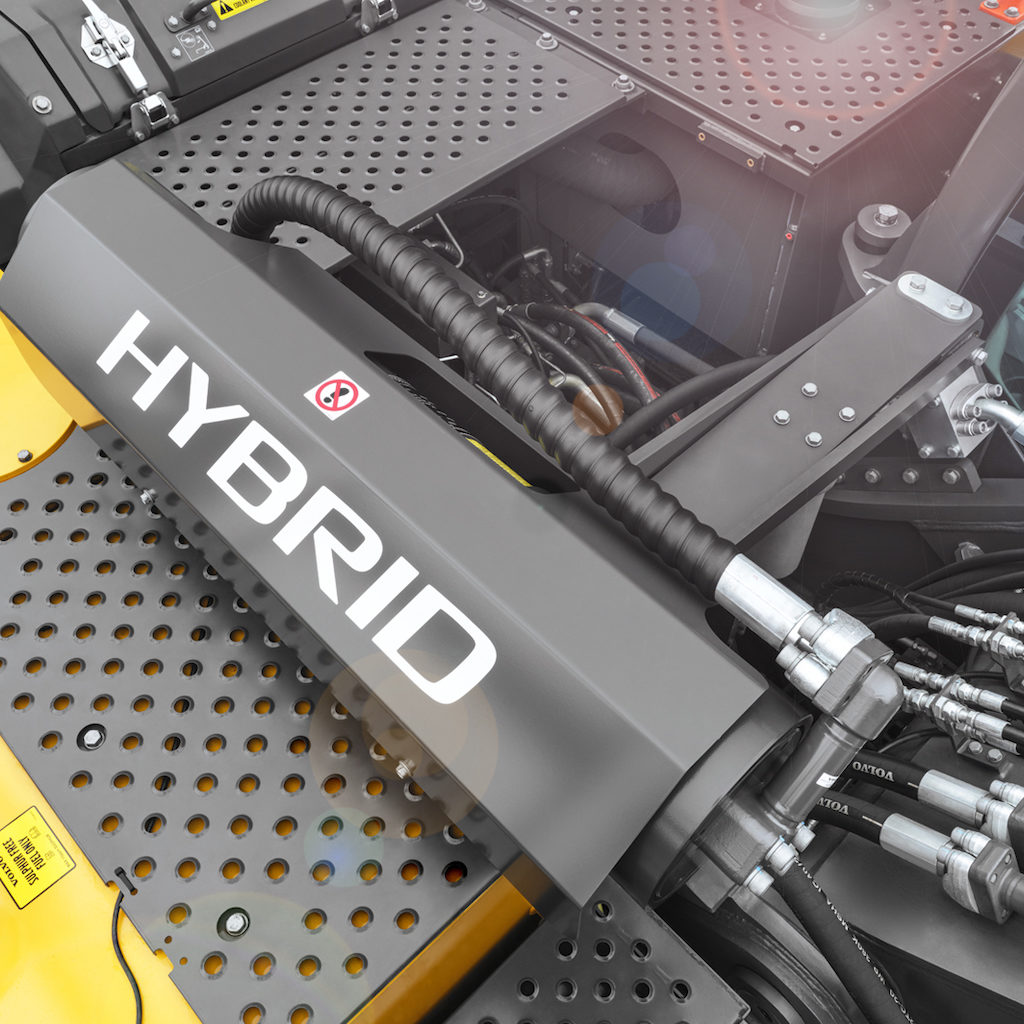

Unlike other hybrid systems, the componentry on these machines is relatively simple, consisting of minimal add-on components that are easy to maintain. The extra energy boost which the hybrid system is able to offer helps take load off the engine, and in the process delivers the improved fuel efficiency of up to 17% and up to 15% less CO2 emissions – particularly important when working in urban areas. When used in ‘dig and dump’ applications (especially those within a 90o swing) this straightforward approach offers rapid payback.

EC300E HYBRID IN FOCUS

While the EC250E Hybrid and EC350E Hybrid are all new, the EC300E Hybrid has been comprehensively upgraded. New features include:

- 10% improvement in fuel efficiency, thanks to intelligent electro-hydraulic and new D8M Volvo engine – which reduces rpm from 1,800 to 1,600, while delivering a 5% increase in power.

- A 700 kg heavier counterweight, providing greater stability and a 5% increase in across-lifting capacity.

- New priority functions – allowing operators to prioritize one function, Boom/Swing and Boom/Travel, over another.

- New adjustable boom-down speed control – ideal for precision tasks.

- Improved response times – thanks to electric control joystick and fully electric travel pedals.

There are also improvements in operator comfort, including a new boom-and-arm bounce reduction technology – which lessens machine shock – and new optional Comfort Drive Control, which helps reduce fatigue by enabling operators to steer the machine using the joystick rollers instead of the pedals. When it comes to conducting maintenance, accessing the upper structure is made easier, thanks to the new 3-points right-hand side access. Also, a new splash guard on the urea tank makes filling easier and reduces the risk of spillages, while engine oil and filter change intervals have been doubled to 1,000 hours.

The new EC250E Hybrid, EC300E Hybrid and EC350E Hybrid have cutting edge technology that saves fuel, lowers emissions, and improves project profitability