Hyundai Construction Equipment has the technology to enhance your fleet management.

Boosting uptime, increasing productivity and driving safety is the aim of all who operate in the plant sector and Hyundai Construction Equipment is providing the technology to achieve those ambitions. The South Korean manufacturer provides a whole suite of technologies including its Hi SITE construction site management tool, and Hi ASSIST machine guidance and control systems. There’s also real-time diagnostics and preventative maintenance through Hi CARE, whilst site safety improvements can be accrued with Hi DETECT

Hi SITE

The Hi SITE construction site management system uses Hyundai Group’s XiteCloud to power digital analysis and visualisation of projects. The system takes inputs from a range of sources, including drone surveys and traditional construction drawings, bringing together technologies to create a single, easy to access, job site resource.

This data source can then be used to create operational planning, with estimation, quantity surveying and work volume calculations built in. The information is made available to management technology systems and site automation, reducing build times, cutting construction costs and increasing productivity for the contractor.

Hi ASSIST

Hyundai’s Hi ASSIST range of machine guidance and machine control systems has been developed in cooperation with industry-leading provider Trimble Earthworks. The systems can be used to provide two-dimensional guidance and control, or three-dimensional machine control of the company’s A-Series excavators.

HCE has also developed a range of remote-control operating solutions, that provide increased customer safety and efficiency in hazardous operating conditions. There are currently three solutions under development, including a mobile app, a remote-control console and a full remote-control station.

Hi DETECT

Hi DETECT is part of Hyundai’s safety technology, detecting the environment surrounding a working machine, to issue warnings to the operator and prevent workplace accidents. The system, which protects both workers on site and other construction assets, is developing into an active safety technology, using artificial intelligence to recognise and control machine operations.

The system incorporates RDS (Rear Detection System) that uses radar to detect objects and automatically warn the driver of potential impact. This proven technology is not influenced by weather or light, so can be used at all times in all site conditions.

Hyundai’s SGS (Smart Guard System) is a smart obstacle detection technology that uses sensors around the machine with a deep learning function. The system emits visual and audible warnings when it detects a person within its working envelope.

The company has further developed its AAVM+ (Advanced Around View Monitoring) system for wheel loaders. This next-generation system will be launched in 2023, combining rear radar sensors, a steering angle sensor and the AAVM system, significantly improving safety to the rear of a loader. Like an automotive parking system, the technology displays the intended area of operation, highlighting hazards and reducing blind spots for the operator. The AAVM+ system defines the warning/danger zones, keeping false warnings to a minimum.

E-Bounds are a virtual electronic boundary or geofence that can be pre-set by the operator on site or by the manager in the office. The machine’s work equipment will not function beyond the electronic boundary, protecting personnel and facilities on site and preventing unauthorised machine use.

Hi CARE

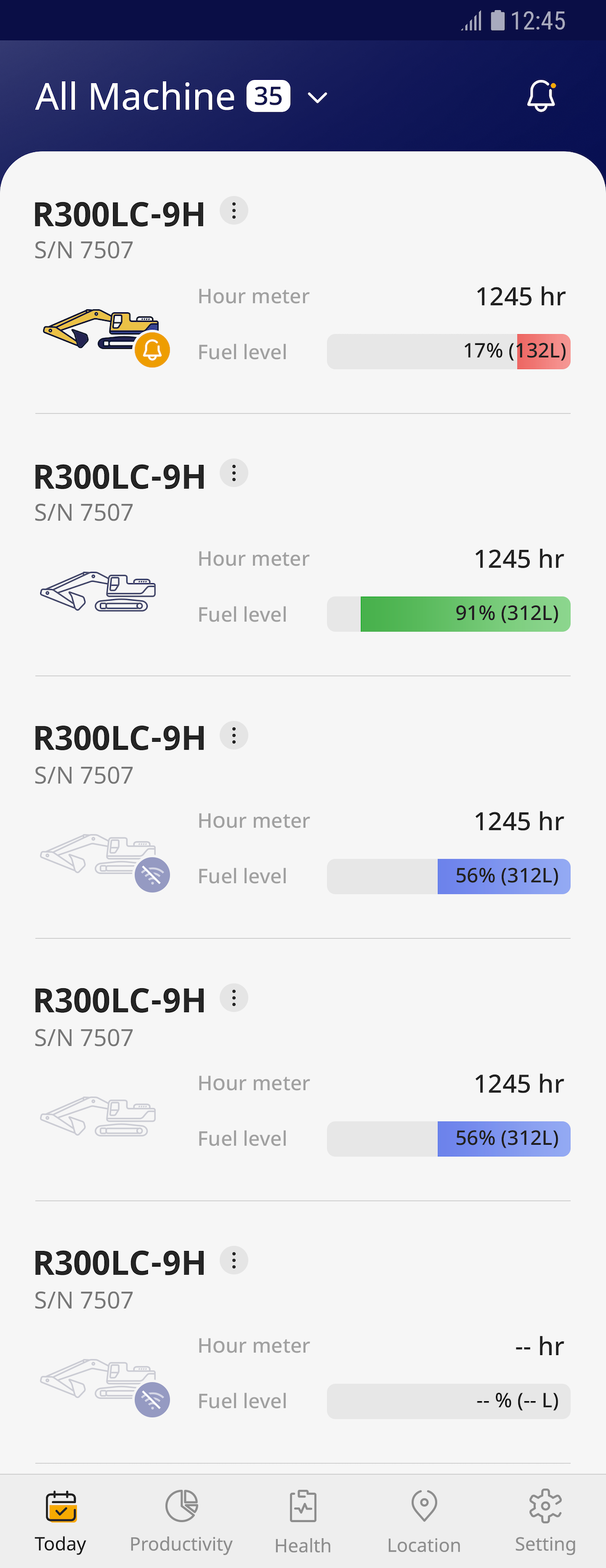

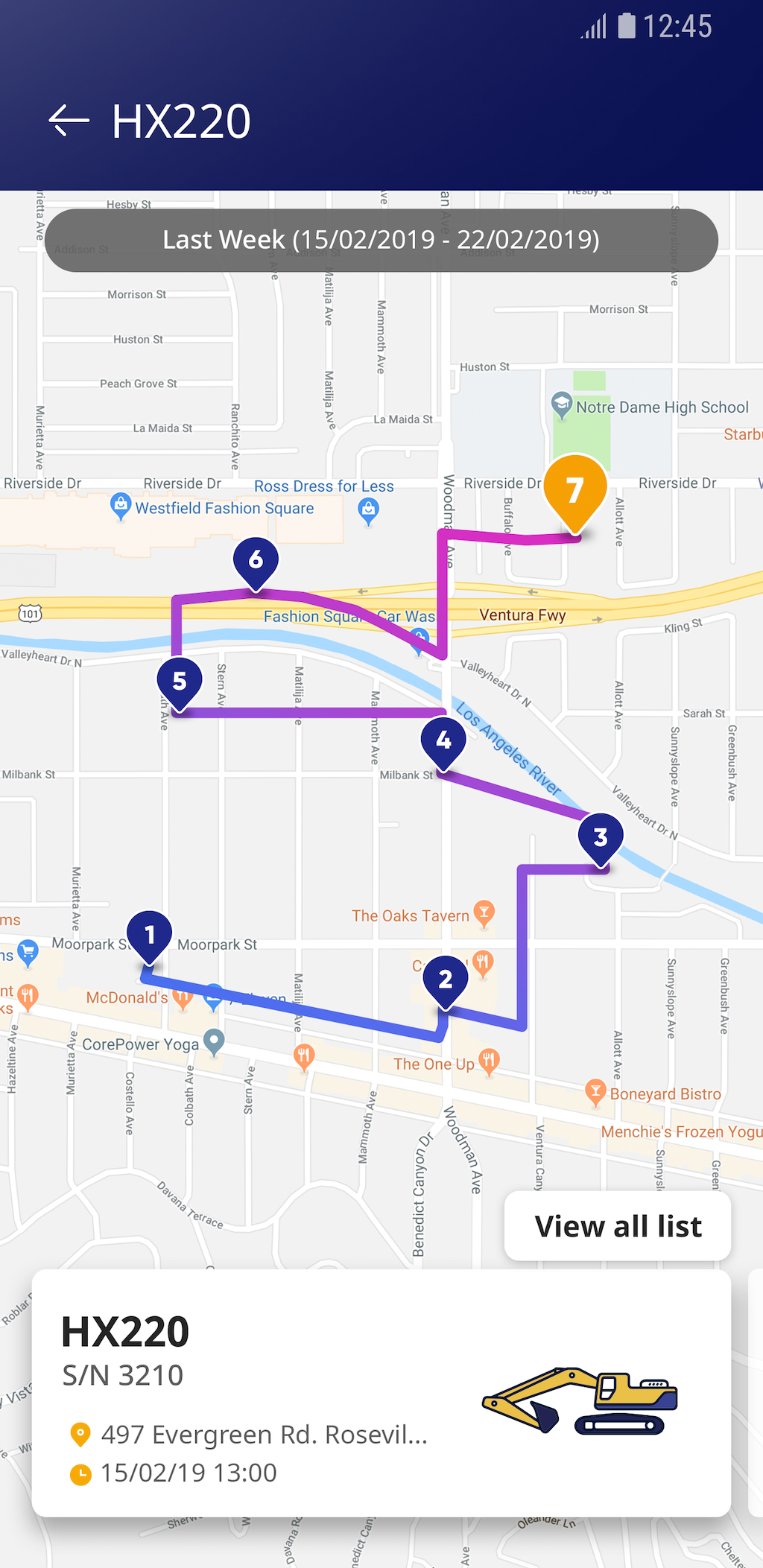

Through the use of HiMATE telematics customers have access to real-time diagnostics for preventative maintenance. The system can deliver operational reports and can be used to set geofenced working areas. Working through the HiMATE website, operators have access to troubleshooting guides, while fleet managers can access monthly equipment reports through the Fleet Manager app.

Third-party fleet management systems can also make use of Hyundai’s Hi CARE technology, with standard protocol APIs allowing the transfer of data to external operating systems. Hyundai is also working with engine supplier Cummins to deliver ECD (Engine Connected Diagnostics), making it easier for engineers to pre-diagnose faults and to ensure single-visit repairs on site.