By increasing the safety and speed of attachment changes, whilst also expanding the versatility of an excavator, quick-couplers are seen as game-changers in the construction industry.

But in this era of fast-moving technology and ever-changing construction sites, the humble coupler is now something many contractors take for granted.

Driven by the demand for added safety and efficiency, quick coupler designs have changed dramatically over the last two decades and advances in materials are helping manufacturers like Miller UK, to keep finding new ways of making couplers lighter for fuel efficiency and stronger to enhance life cycle.

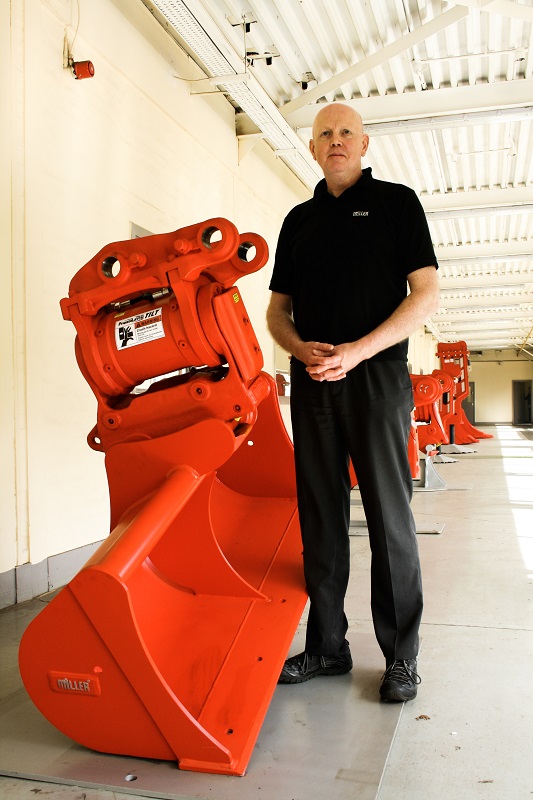

The science behind the design and development of next generation couplers is an art, as Steve Ferguson, Engineering Manager at leading earthmoving attachments manufacturer Miller UK, explains.

“More often than not, users will look at specifying a coupler thinking that all quick couplers share the same properties. Miller Coupler technology has developed to meet the needs of all types of working conditions, driven by the requirements of contractors to carry out work efficiently without compromising on safety or economy.

The right coupler should complement and enhance the machine and make each task as smooth and efficient as possible, saving contractor’s fuel, time and money. Put simply, specifying the wrong coupler will cost more in the long run.”

The right coupler should complement and enhance the machine and make each task as smooth and efficient as possible, saving contractor’s fuel, time and money. Put simply, specifying the wrong coupler will cost more in the long run.”

Thinking inside the box

There is often a misconception in the construction industry that steel castings are brittle and subject to abrupt failure, however brittleness is a function of metallurgy, not of process, and steels are not brittle alloys.

Compared to fabrications, which are assemblies of steel components that have been welded together to form a larger part, quick coupler castings are a single piece created by running high quality molten metal alloys into a cast, resulting in a homogenous single piece free from joints.

In general castings provide better tolerances and superior mechanical properties when compared to fabricated assemblies.

Miller UK is one of the leading pioneers in the development of cast couplers, having set up their casting joint venture in China since early 2004 after a period of four years of intensive supplier development.

Their continual R&D investment has played a pivotal role in enhancing British cast designs and delivering standardised OEM approved management processes in conjunction with their Chinese counterparts for over 13 years.

Casting allows Miller design engineers to explore exciting profiles of its quick couplers as it enables complex curved geometrical frames that are impossible with fabricated assemblies.

The major advantage of cast couplers is that they are specifically designed and engineered exclusively to meet specific lightweight performance design objectives with no extra pieces, weld or sections. Simply put, castings allow designers to put metal and strength only where it is needed.

In contrast, the formation of a fabrication is typically driven by the availability of material, and the ability to join the parts. “The weakest part of a fabricated assembly will always be the weld” commented Steve who added: “More often than not welds are usually placed in the highest stress locations, such as corners, which limits the load bearing strength of the coupler.

In a high cycle product such as a coupler even the grade of steel being used will have little impact on the fatigue performance as the fatigue limit on a structural weld is considerably lower.”

To combat this, welded fabrications often can be redesigned to one-piece casting, which allows the designer to effectively remove highly stressed areas using advance finite element analysis (FEA).

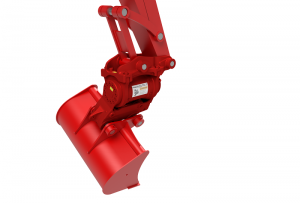

An example of the latest cast design to come from Miller UK R&D facility in Northumberland UK is its newest lightest and strongest PowerLatch Tilt Coupler. Designed specifically to offer up to 180o tilt rotation for 3.5T up to 20T machines whilst handling the extreme ground conditions in Australia and has recently released to the UK market at Plantworx 2017.

“We have listened closely to the requirements of our customers and we were set with the task of lowering the design height of the original PowerLatch Tilt coupler and coming up with a novel way of offering late dedicated top mounted brackets.

“This offers not only additional strength to the actuator connections but to also offer interchangeable top brackets,” said Steve. “The solution, although simple, was game changing – all thanks to the design flexibility that casting provides.”

The manufacturer’s design team developed a fully cast coupler body, which offers up to 180o tilt rotation and utilises the trusted Twinlocking PowerLatch technology in combination with a truly innovative top mounted cast head bracket.

Miller have managed to deliver the lightest tilt frame in the marketplace with the lowest profile to offer optimised breakout force whilst increasing strength in traditionally highly stressed areas.

Furthermore, the top bolted attachment method removes a notoriously troublesome welded connection seen in a number of other tilt couplers available on the market.

With its fully cast, slim line, external cylinder free tilt design, the new PowerLatch Tilt coupler is ideal for working with the narrowest of attachments for all manner of tasks, from channel clearing and grading to house building and quarrying, all without having to worry about damaging external rams or cylinders.

Summary

Combining multiple elements together in fabrication assembly generates stress points, requiring additional strength to be designed back in. Fabrication design needs to be sensitive to the limitations: welds can be hard to repair and are often the cause of failure.

In contrast the ability to explore inspiring, complex curved geometrical cast frames, which allows designers the ability to add strength where needed and remove excess weight where not required, offers an exciting level of design flexibility when compared to traditional fabricated couplers.

The tough, ductile nature of castings therefore lends themselves to designs where longer working life and improved performance across all work environments are an advantage. For once thinking inside the box offers a new perspective on coupler technology.

For further information on Miller UK click here.