OnGrade helps Hughes and Salvidge achieve safer demolition operations at Heathrow site using RFID proximity warning system.

Tony Jack, SHEQ (Safety, Health, Environment and Quality) manager at Hughes and Salvidge saw how well SiteZone was performing to improve safety in the fleet and prevent collisions between workers on foot and vehicles at one of its subsidiaries, Aasvogel Skip Hire and Waste Management.

He and Hughes and Salvidge Airport Contracts Manager, Danny Byng therefore, decided to use SiteZone for Hughes and Salvidge’s demolition operations at London Heathrow Airport (LHR).

Tony says:“We didn’t want to use this safety system because we were asked to, we wanted to initiate the system as a key part of every project we do at the Airport – where plant and on-ground personnel are working in close proximity.”

How SiteZone works

To appreciate better why Hughes and Salvidge wanted to use SiteZone on their demolition plant, it’s important to understand exactly how the system works.

In workplaces where collisions between vehicles and workers on foot are a potential risk, the familiar precautions can sometimes need additional support. In poor visibility conditions, standard PPE or even cameras have proven fallible.

The use of reversing beepers and other sound alarms also have limited efficacy since workers can be wearing ear protectors and may not be aware of oncoming plant. Therefore, it’s vital that both drivers and pedestrians know, clearly, when they are in each other’s danger zones.

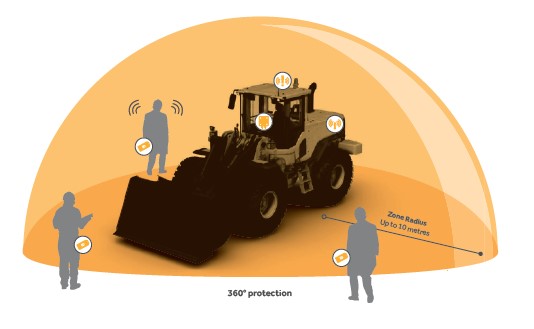

In these situations, radio frequency identification (RFID) proximity warning systems, like SiteZone offer a new dimension on site safety. SiteZone gives all site workers an extra level of control and protection. It can see around corners, through dust and smoke and in poor light conditions.

Site vehicles are fitted with RFID detectors, while pedestrians have RFID emitters fitted to their hard hats or sleeves. When a pedestrian enters the danger zone of a vehicle, both the pedestrian and driver receive tactile, visible and audible warnings. They are not easily ignored!

The wearable RFID tag vibrates, making the pedestrian aware of the vehicle, while the driver is alerted by sound and flashing lights in his cab. This two-way alarm provides a means to vigorously alert both site worker and vehicle operator that collision between them is imminent unless they stop and re-assess their positions and move out of harm’s way.

The challenges of applying SiteZone at the LHR site

Demolition is a high-risk activity and more so on a confined site like LHR where Hughes and Salvidge is operating. The airport is a challenging demolition site because of the special access requirements, confined conditions and size of rigs in use. Hughes and Salvidge is using big demolition rigs, where certain operations can limit visibility for the plant operator.

When first approached, the OnGrade team knew that setting up Hughes and Salvidge’s safety zones wasn’t going to be straight forward. OnGrade undertook a detailed site visit and gave recommendations on how the system could be configured to fulfil each of Hughes and Salvidge’s safety needs on site.

LHR is not a conventional demolition site, and Hughes and Salvidge’s controlled demolitions require thorough and specialist site set-up procedures, segregation methods and management throughout every project.

The reason being that LHR is a much more controlled environment; as Hughes and Salvidge are demolishing old piers they are operating airside at a working terminal, with aircraft, staff and ancillary vehicles in the immediate vicinity of the segregated, controlled demolition zones.

Because of this, OnGrade was very aware that it was crucial to have SiteZone configured precisely from the start. Access to the LHR site is complex and lengthy due to the high level of security protocols. An OnGrade team member couldn’t just ‘pop in’ on a callout to adjust or fine-tune the system.

Therefore, careful assessments and measurements were taken for each rig in the context of its working environment on site to avoid the risk of having to return and adjust any setting discrepancies.

Part of the rigorous configuration involved installing the system on trial for a several weeks on one rig. This is where the required detailed adjustments were made and subsequently, Hughes and Salvidge now use the SiteZone System on all six of their machines in operation on multiple projects at Heathrow. This includes 30-tonne and 47-tonne excavators on the LHR site.

A big part of the OnGrade ethos is about educating workers on collision risk. It’s not enough just to install the SiteZone system without really understanding why and how it works. The company carried out a suite of toolbox talks for staff on the ground. Even though the workforce was a truly international one and overcoming language barriers was a potential challenge, SiteZone is so easy to use, and there was little difficulty in instructing the workers.

A big part of the OnGrade ethos is about educating workers on collision risk. It’s not enough just to install the SiteZone system without really understanding why and how it works. The company carried out a suite of toolbox talks for staff on the ground. Even though the workforce was a truly international one and overcoming language barriers was a potential challenge, SiteZone is so easy to use, and there was little difficulty in instructing the workers.

Client benefits of using SiteZone

As OnGrade used their ‘EasyFit’ kit to install SiteZone, it enables easier transfer between machines. The EasyFit option has all the functionality of the standard system, but is an ‘express’ installation version. It allows SiteZone to run off a machine’s auxiliary power rather than from the mains.

Furthermore, the system is attached using high strength magnets and window mountings to keep the system securely in place on the vehicle, and installation takes no more than about 35-40 minutes.

SiteZone also collects essential data in the event of a zone breach which can be transmitted and viewed on the Cloud and helps managers monitor and improve site safety.

Hughes and Salvidge site managers have full access to the system via a dedicated log-in, which enables them to view information such as the number of unauthorised entries into a safety zone and a real-time display of length of time spent within them.

By generating this information, performance reports can be created to highlight key ‘hot spots’ on site, within specified zones or specific personnel safety breaches.

As SiteZone has been so successful at LHR, Hughes and Salvidge is rolling the system out on other sites. It is now in use at Wilton International (chemical plant). Tony Jack remarks on the effect of using SiteZone at their Heathrow site:

“The feedback already from our LHR plant operators, on-ground personnel and our clients has been excellent. As an employer, it has given us great satisfaction that we have provided an extra element to our already stringent Health and Safety processes to help keep our staff safe.”

For more information click here.