With just weeks to go until the doors open to Bauma 2019, Bosch Rexroth has unveiled what it will be showcasing at this year’s event, including an array of its innovative solutions which are designed to facilitate greater levels of efficiency and productivity for machines and their operators.

As global regulatory requirements around exhaust and noise emissions become increasingly restrictive, coupled with challenges such as rising fuel costs, the demands of construction machinery are constantly changing. Visitors to Bosch Rexroth’s stand at Bauma 2019 will discover an array of solutions to navigate the shifting environmental landscape, including:

Virtual Bleed Off (VBO) second generation

Paving the way for electronification, as well as supporting manufacturers to overcome environmental challenges, Rexroth has further advanced its VBO flexible drive and control system – and visitors will be able to get hands on at Bauma 2019. As a closed centre excavator system, it gives the operator the same agreeable load sensitivity as an open-centre system while delivering benefits through three core components: the A28VO variable double pump, supporting environmental goals and offering compact design for easy installation; the RC main control valve, which can be installed both vertically and horizontally to give OEMs greater flexibility for differentiating their machines; and the RC electrical control unit with VBO 2nd Gen software with open software architecture to offer freedom and customisation.

BODAS eDA

Characterised by the comfort and reliability for which Rexroth’s hydraulic DA controls are known, the eDA is particularly well-suited to wheeled loaders, telescopic handlers and fork lift trucks, as well as a host of other applications that previously used DA controls. Complete with a fully-electrified A4VG drive pump and A6VM hydraulic motor, the electrohydraulic solution offers a comprehensive package that includes the electronic, speed-dependent control of hydrostatic gearboxes and opens up new machine concepts and target markets for manufacturers with its optimal system design.

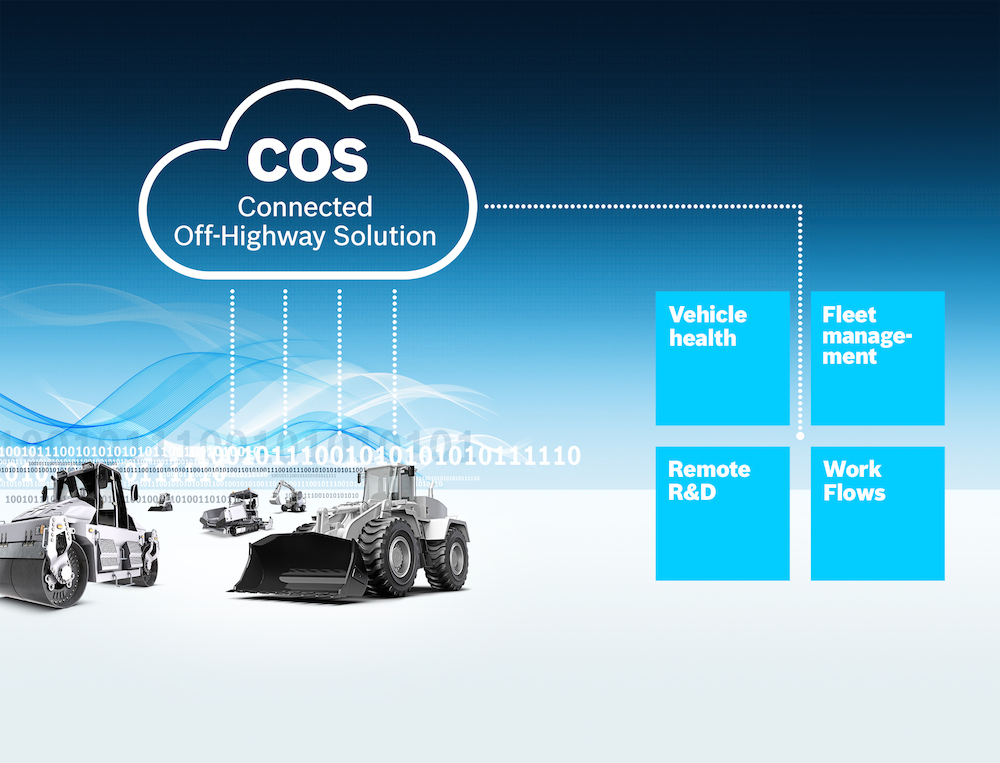

Connected Off-Highway Solution

With the Internet of Things (IoT) becoming increasingly relevant for mobile working machines, Rexroth’s Connected Off-Highways Solution builds on the international success of Bosch’s IoT Suite – to which more than three million vehicles are already connected – with sector-specific configurations. Created specifically to meet the needs of the fleet management, vehicle health, remote R&D and workflows sectors, it is available as an end-to-end solution and as individually-selectable modules which can be integrated into existing IoT set-ups, linking seamlessly to third-party systems. Connecting vehicles and their sub-systems via the cloud, the system enables OEMs to design their own applications for their industry – be it making predictions around machine health and maintenance or tracking the location of vehicles in fleet management.

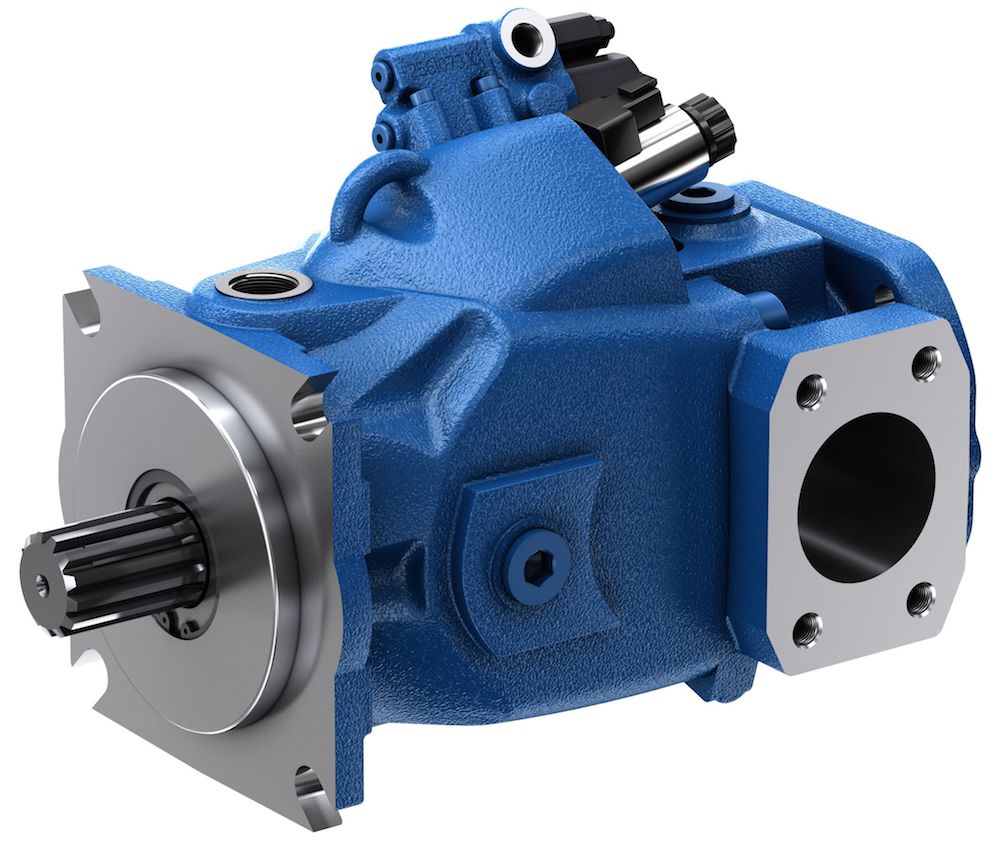

Axial piston variable pump – A10VOH

Hydraulic units are at the centre of construction machinery and are required to be reliable and robust in the face of extreme conditions, as well as space-saving and energy efficient. Designed for applications with a pressure level between medium (280 bar) and high (350/380 bar), the A10VOH bridges the gap to create a solution which facilitates efficient operation for users. With a permissible nominal pressure of 320 bar in corner power operation, and 350 bar when the swivel angle is reduced, the lightweight and compact A10VOH is perfectly suited to steering drives, hydrostatic fan drives and working hydraulics.

eGFT8000

Just as passenger and freight transport has begun to benefit from electromobility, applications which have traditionally used diesel-powered working machines are now being transformed by emission-free alternatives. Enabling an electric motor to be used in high-mileage mobile working machines, without the need to change installation space and gear geometry, the eGFT8000 facilitates emission-free mobility. Utilising a high-speed electric motor instead of a hydraulic motor, the compact drive results in a space-saving drive unit which serves as a drive component for wheeled or track-mounted vehicles and other mobile equipment. As an emission-free drive, Rexroth’s eGFT8000 is perfectly suited to vehicles used in tunnelling and enclosed spaces, in addition to construction machinery used in inner city spaces.

Radial piston motor MCR-S

As mobile construction machines become increasingly sophisticated, their individual components must evolve to cater for these demands. Delivering on efficiency, the MCR-S radial piston motor for chain drive applications provides a compact solution. Featuring a repositioned parking break, integrated two-speed shifting spool within the motor distributor and optimised port locations, the motor is up to 33% shorter, 41% lighter and fully optimised for ease of installation. The result is greater levels of efficiency without the need to compromise on durability.