Construction Plant News talks exclusively to Skyjack about some of the latest developments from the access and material handling specialist.

What moves is Skyjack’s making into electrification and battery powered units? Not just in scissors and vertical masts but also in articulated and telescopic booms?

Skyjack is currently in the process of developing its first hybrid/electric booms. The demand for such products is continuing to grow throughout the world and we recognise we need to also offer products to meet this demand – including products that currently have limited offering with hybrid/electric powertrain.

While demand for straight electric is growing, the immediate demand is stronger for traditional engine/electric hybrid machines. There are a number of other alternative hybrid developments going on (i.e.. hydrogen fuel cells, hydrogen combustion engines) but currently there are fewer restrictions, such as charging infrastructure, efficiency, cost, fuel availability, on a traditional hybrid and that is why our focus is on that type of powertrain (as well as pure electric).

Are there any specific trends that Skyjack is seeing in terms of platform capacity or specific attachments?

Several current trends have been primarily driven by changes to emissions and design standards. Electrification is obviously a growing trend for rough terrain equipment in Europe, while design standard changes has made manufacturers rethink how machines have been used and how they are best suited for meeting jobsite demands.

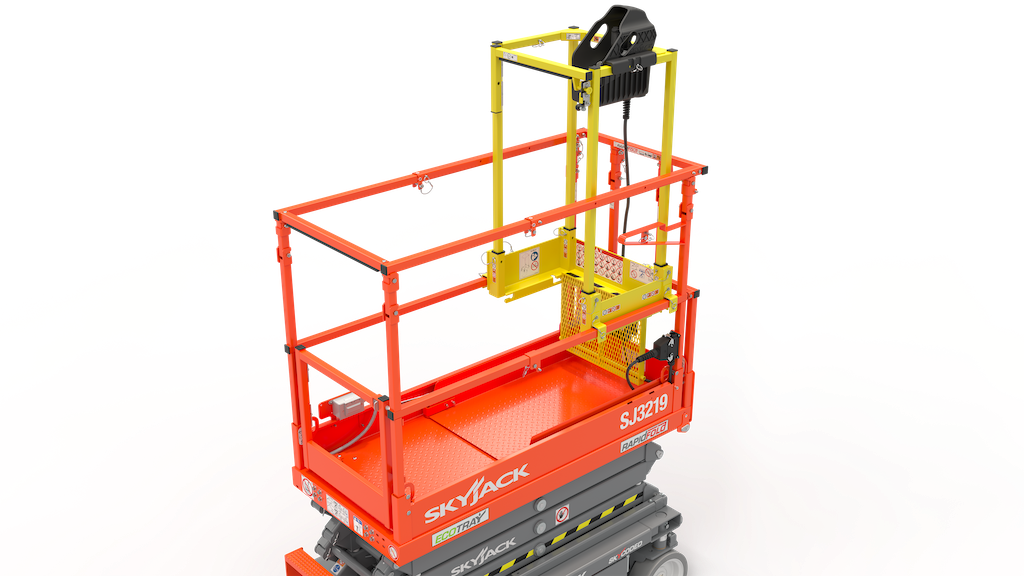

We’ve also seen an increased demand for productivity options and in response we have just launched our new XStep. Designed to be used in conjunction with our compact SJ3215 and SJ3219 models, XStep increases working height by 19” by providing operators with a safe and secure way of access into and around tight, restricted spaces, such as ceiling openings and ceiling mounted structures. Since it is an ACCESSORYZER it can be ordered from our parts department. With new machines, it can be installed and removed in minutes with no special tools needed and is also backwards compatible to the previous SJIII models.

What are some of the key features and benefits of the new SL12 E, SJ16 E and SJ20E vertical masts?

The new SJ12 E and SJ16 E are driven by dual AC Electric Motors which provides up to 30 per cent improvement in duty cycles, meaning less charging, less power consumption, and a lower carbon footprint. We have also achieved a 70 per cent reduction in hydraulic connections.

The SJ12, SJ16, SJ20 E have working heights of 5.48m, 6.55m and 7.77m respectively. The top of the mast on the SJ12 E and SJ16 E is now in line with the platform rails, which is beneficial for overhead work, especially where there are drop ceilings. Included in the new products is a dual “load cell” overload system designed with both indoor and outdoor use in mind. The SJ12 E comes with a standard wind rating, and the SJ16E and SJ20E feature an optional wind rating for one person.

Other notable features include:

- 90-degree steering with a zero inside turning radius.

- A simple, maintenance free, and fixed pothole protection system.

- Forklift pockets located at the rear of the base with tie down and lift points at each corner.

- Onboard CAN enabled control unit and multi-voltage “smart” charger; and

- Onboard diagnostics display with simple and plain language readouts.

Can you explain the ECO mark? What standards and machine specifications are required for a machine to be accredited it, and what it is intended to convey to customers?

The ECO mark was introduced to highlight the features on Skyjack machines that make them sustainable products, from the perspective of both their operation and construction. Various machines now feature updated machine livery and information on literature has been added to identify both existing features as well as improvements that make them sustainable products. We are focusing on not only making improvements to our products but also highlighting some of the features that already exist on the machines that help our customers improve their impact on the environment. We launched the ECO label on the recently introduced SJ12/16 E models to highlight how we’ve been able to bridge practicality with sustainable efficiency by decreasing a products overall carbon footprint. The ECO label also is accompanied by relevant information in the form of an ECO Matrix that details what constitutes the improvement in sustainability.

From feedback from operators are there any specific features of Skyjack machines that end users point to as being especially useful in the field?

Along with machine reliability, these are some of the key features that our customers and end users appreciate about our products. Below are some examples used across multiple products/ranges.

- AXLDRIVE

Low maintenance axle-based drive system gives positive traction and excellent rough ground terrain ability. This means Skyjack Rough Terrain Scissor Lifts and Boom Lifts can be used in the most challenging of conditions. - EASYDRIVE

Unique boom feature only utilised by Skyjack where the boom lift controls are always in the orientation of the boom regardless of position of turret over chassis. Reduces operator confusion by eliminating the need for color coded arrows to determine drive versus joystick direction. - SKYRISER

Ensures that the riser – and main pivot point connecting the fly boom to the riser – travel in a straight vertical line. Movement in a true vertical manner, without drifting forward or back, this reduces the amount of repositioning the operator needs to do in order to stay close to a building facade, improving productivity. - SMARTORQUE

Using an optimised balance of engine horsepower, torque, and hydraulic performance, Skyjack SMARTORQUE products deliver the same on-site job performance as higher power units – providing excellent performance with less engine horsepower. Less emission controlling components avoids the cost associated with their complexity, as well as the time and inconvenience required in maintaining them. SMARTORQUE means no Diesel Particulate Filter (DPF), no Diesel Exhaust Fluid (DEF)/AdBlue, and no other active exhaust after treatment.